Mas01

Member

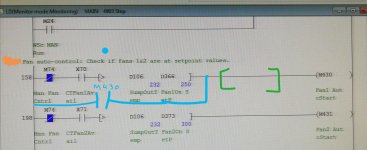

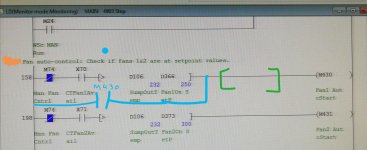

We've got 2 cooling fans on our system. They switch on based on water temperature. One switches on at 25c. The other switches on at 30c. The code works okay, but I noticed that the fans are switching on/off and jittering due to slight fluctuations in water temperature at/near the setpoint values. I want to add some sort of "deadband"/debounce to stop the jitter. I was thinking of 5 Celsius below the setpoint to switch the fans off.

To do this:

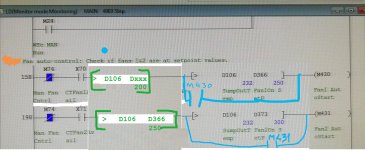

In the green brackets I was going to put:

[> D106 D366 - K5 ]

And also add M430 as shown by the blue line.

I'm not sure if D366-K5 will be recognised or if I need to create another D-register equal to D366 minus 5.

Does this logic look correct? Thanks

To do this:

In the green brackets I was going to put:

[> D106 D366 - K5 ]

And also add M430 as shown by the blue line.

I'm not sure if D366-K5 will be recognised or if I need to create another D-register equal to D366 minus 5.

Does this logic look correct? Thanks