dear,

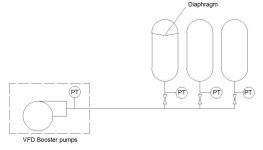

i have booster pumps that are running on pressure based on the pressure transmitter that comes with the booster pumps kit and there are pressure transmitters on each pressure vessel(please refer to below picture). Pumps and all the instruments are being monitored by a SCADA system.

my question is: are the pressure transmitters on each pressure vessel are necessary? from common practice i mean.

From my understanding is that if diaghragm is broken, pressure in the system will remain the same as measured with the pressure transmitter that comes with the booster pumps kit, what will change is the running frequency of the booster pumps, so that the operator in the SCADA will know that something wrong has happened.

in what sense are these pressure transmitters on the pressure vessels are necessary and if they are really important to be kept.

thanks for your feedback.

i have booster pumps that are running on pressure based on the pressure transmitter that comes with the booster pumps kit and there are pressure transmitters on each pressure vessel(please refer to below picture). Pumps and all the instruments are being monitored by a SCADA system.

my question is: are the pressure transmitters on each pressure vessel are necessary? from common practice i mean.

From my understanding is that if diaghragm is broken, pressure in the system will remain the same as measured with the pressure transmitter that comes with the booster pumps kit, what will change is the running frequency of the booster pumps, so that the operator in the SCADA will know that something wrong has happened.

in what sense are these pressure transmitters on the pressure vessels are necessary and if they are really important to be kept.

thanks for your feedback.