JLand

Member

Hi folks,

I am upgrading a SLC to a ControlLogix platform. The goal of the project isn't simply to get the same program to run on different hardware (which Rockwell makes easy), but instead to rewrite the program using modern standards to improve ease of use and troubleshooting.

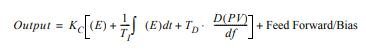

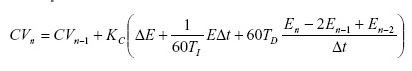

Part of this is I would like to convert the SLC PID to a PIDE (which I prefer from a programming standpoint and is the more modern instruction anyways). SLC PID to CLX PID seems easy, just be sure your settings (execution time/STI mode, control action, equation form, tuning parameters, etc.) match between the two projects.

However, this is a bit more difficult as PIDE uses the velocity equation instead of the position equation used in PID, changing the transfer function, meaning the tuning parameters are no longer equivalent.

For reference, the PV is the level of a tank, the CV is the speed of a VFD for a positive-displacement pump feeding into the tank, we are using a dependent equation, normal acting direction. The goal is to duplicate (or come as close as possible) the control of the original PID, not necessarily improve the control of the PID. The original controller gain is 20, reset is 1min/rpt, and rate is 0.01min (I did not come up with these values). I will have to do a similar conversion to a steam heat exchanger TIC as well.

I've been tinkering for a bit and can't seem to crack it. Can someone lend me a hand? Would it be best to just put in a PID instruction instead?

I am upgrading a SLC to a ControlLogix platform. The goal of the project isn't simply to get the same program to run on different hardware (which Rockwell makes easy), but instead to rewrite the program using modern standards to improve ease of use and troubleshooting.

Part of this is I would like to convert the SLC PID to a PIDE (which I prefer from a programming standpoint and is the more modern instruction anyways). SLC PID to CLX PID seems easy, just be sure your settings (execution time/STI mode, control action, equation form, tuning parameters, etc.) match between the two projects.

However, this is a bit more difficult as PIDE uses the velocity equation instead of the position equation used in PID, changing the transfer function, meaning the tuning parameters are no longer equivalent.

For reference, the PV is the level of a tank, the CV is the speed of a VFD for a positive-displacement pump feeding into the tank, we are using a dependent equation, normal acting direction. The goal is to duplicate (or come as close as possible) the control of the original PID, not necessarily improve the control of the PID. The original controller gain is 20, reset is 1min/rpt, and rate is 0.01min (I did not come up with these values). I will have to do a similar conversion to a steam heat exchanger TIC as well.

I've been tinkering for a bit and can't seem to crack it. Can someone lend me a hand? Would it be best to just put in a PID instruction instead?