Ron Beaufort

Lifetime Supporting Member

I don't think I can post the app.

that's unfortunate ... it's really hard for us to give you detailed information that way – but I understand your dilemma ... don't get yourself in any trouble ...

If the transmitter was scaled -40 to 120, then at 4 mA, I would want to see -40. And at 20 mA, I would want to see 120.

OK – so far ...

But if the transmitter was out of range, I don't want to see those garbage numbers.

now we need to talk ...

the ADVANTAGE to having those "garbage numbers" available might be to let you know that SOMETHING (broken wire, etc.) is WRONG with the system ...

incidentally – that's the MAIN reason why many (most?) instrumentation signals are set up to use FOUR to 20 mA – and not (usually) ZERO to 20 mA ... the value FOUR is often referred to as a "LIVE ZERO" ... so if the processor sees a value less than FOUR, it realizes (for example) that the tank is not just "empty" – and it can take action by (for example) closing a valve until someone can check and repair the system ...

and - many (most?) thermocouple transmitters are set up for "UPSCALE BURNOUT" – which means that if the thermocouple lead breaks, the transmitter will put out a much higher than 20 mA signal – (once again) alerting the PLC that SOMETHING is WRONG with the system - so that it could then turn OFF the heaters - rather than thinking that the furnace is really COLD and turning the heaters wide open ...

TIP: if you're worried about displaying the "garbage numbers" on an HMI (which might certainly confuse an operator) – you can have the HMI display something like a "FAULT" legend when the signal is out of range ...

Isn't there just a bit on the card I can test to see if the value is garbage?

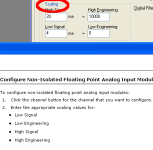

sure – just start reading on page 3-18 [Adobe page 68/184] of the 1769-IF8 User Manual linked below ... some of the bits you can choose from are:

General Status Bit

Low Alarm Flag Bit

High Alarm Flag Bit

http://literature.rockwellautomation.com/idc/groups/literature/documents/um/1769-um002_-en-p.pdf

Then I'll just put it on a Maintenance Display of some kind to tell a tech to check it out during his normal routine maintenance work.

well – just make sure that a "problem" can wait long enough for that "routine" maintenance work to roll around ... you don't want to take a chance on a tank overflowing – or on a temperature running wild – or something else that would fall into the "bad column" on the big clipboard of life's experiences ...

good luck with it ...

Last edited: