Shane.platt

Member

Hi All!

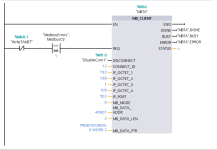

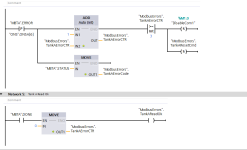

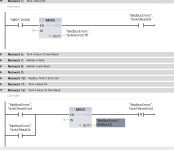

I am having an issue with my Siemens s7-1215C communicating with my Mettler Toledo IND560 scale. The protocol being used is Modbus TCP and the instruction being used in TIA Portal v13 is MB_CLIENT. The problem is happening once or twice a day, sometimes more often. When the problem occurs the Mettler controller is not faulted and is displaying the correct values. However, the Siemens s7-1200's above mentioned MB_CLIENT block is not updating the values, and is frozen on the last good value received. So I am thinking the issue is in the Siemens somewhere.

I reviewed the diagnostic buffer and it appears I am receiving several errors each time this occurs. Some of the errors are

Error: IO device failure - Timeout in RPC application

internal AR error code 16#15

Error: IO device failure - Data transfer fault (no frame received)

internal AR error code 16#0

Error: IO device failure - IO device not found

internal AR error code 16#13

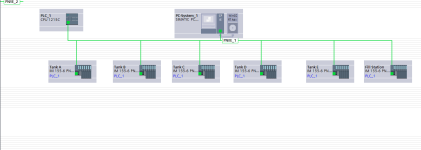

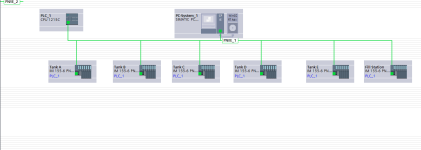

I have attached the log below as well as a screen shot of the network view.

I sure would appreciate any insight you folks might have!!

Respectfully,

Shane

I am having an issue with my Siemens s7-1215C communicating with my Mettler Toledo IND560 scale. The protocol being used is Modbus TCP and the instruction being used in TIA Portal v13 is MB_CLIENT. The problem is happening once or twice a day, sometimes more often. When the problem occurs the Mettler controller is not faulted and is displaying the correct values. However, the Siemens s7-1200's above mentioned MB_CLIENT block is not updating the values, and is frozen on the last good value received. So I am thinking the issue is in the Siemens somewhere.

I reviewed the diagnostic buffer and it appears I am receiving several errors each time this occurs. Some of the errors are

Error: IO device failure - Timeout in RPC application

internal AR error code 16#15

Error: IO device failure - Data transfer fault (no frame received)

internal AR error code 16#0

Error: IO device failure - IO device not found

internal AR error code 16#13

I have attached the log below as well as a screen shot of the network view.

I sure would appreciate any insight you folks might have!!

Respectfully,

Shane