Hello.

I want to know if there is a way to tell if someone is online with a PLC from an specific IP address.

To elaborate my inquire:

there's a PLC with 2 ethernet adapters, one is connected to a 192.168.xxx.xxx network and the other to a 10.20.xxx.xxx network which means, someone can go online with the controller using any of the two networks.

on the other hand, there's a PC with 2 ethernet adapters, enabling access to the PLC through any of the two networks and i want to know if there's a way to tell if the PC is online with the PLC and which network is the person using to connect to the PLC, the 192.168.xxx.xxx or the 10.20.xxx.xxx.

is there a way to add the PC as a device under the PLC's device tree and use a GSV instruction to determine that PC's IP address?

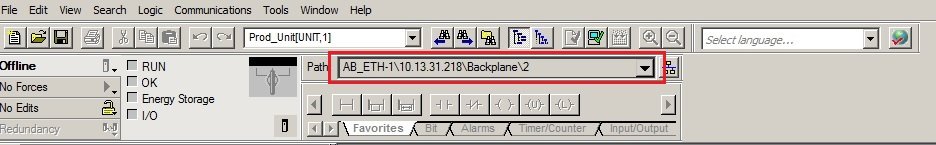

The PLC is an Allen Bradley controller and I'm using RSLogix 5000 v20.04.00/Studio 5000 21.03.02

I want to know if there is a way to tell if someone is online with a PLC from an specific IP address.

To elaborate my inquire:

there's a PLC with 2 ethernet adapters, one is connected to a 192.168.xxx.xxx network and the other to a 10.20.xxx.xxx network which means, someone can go online with the controller using any of the two networks.

on the other hand, there's a PC with 2 ethernet adapters, enabling access to the PLC through any of the two networks and i want to know if there's a way to tell if the PC is online with the PLC and which network is the person using to connect to the PLC, the 192.168.xxx.xxx or the 10.20.xxx.xxx.

is there a way to add the PC as a device under the PLC's device tree and use a GSV instruction to determine that PC's IP address?

The PLC is an Allen Bradley controller and I'm using RSLogix 5000 v20.04.00/Studio 5000 21.03.02