grnick50

Lifetime Supporting Member

Hello all,

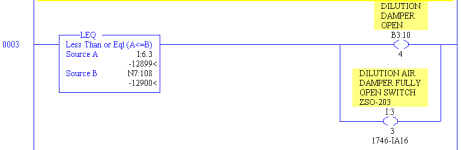

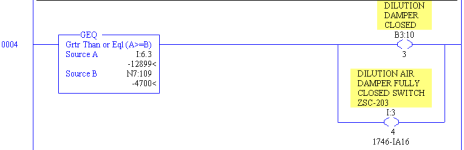

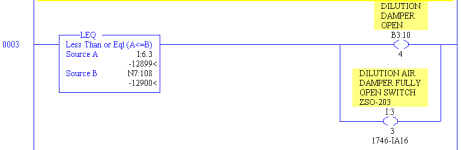

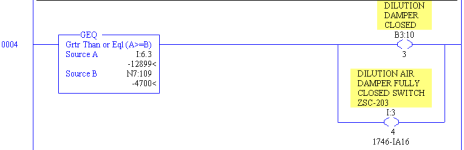

I came across the logic of the attached photos where the programmer is using an analog value to write on two inputs.

My guess is that the original intention was to use the two inputs I:3/3 and I:3/4 but these inputs where not available. Instead an analog input was used, and using some compares the programmer wrote on inputs I:3/3 and I:3/4 to "create them".

That is my guess, but what I don't understand is the values used in the compare blocks.

Any thoughts will be helpful.

I came across the logic of the attached photos where the programmer is using an analog value to write on two inputs.

My guess is that the original intention was to use the two inputs I:3/3 and I:3/4 but these inputs where not available. Instead an analog input was used, and using some compares the programmer wrote on inputs I:3/3 and I:3/4 to "create them".

That is my guess, but what I don't understand is the values used in the compare blocks.

Any thoughts will be helpful.