sparkytex

Lifetime Supporting Member

Hey guys,

I Would like to create an average of an analog signal. I have a transducer feeding a 4-20mA signal to my Analog input channel for current read out of a motor. The problem is the signal fluctuates a lot as the Current Transformer isn't really meant for such a low amperage.

It's a .75HP motor and it only draws at max 2.0 amps when running and the CT is for between 2-25A. The signal fluctuates a lot so It's difficult for the operator to read the running feedback on the HMI. So I'd like to average the current over 5 seconds to "Slow It Down".

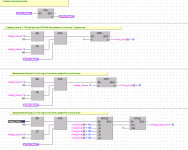

Would like to know the easiest way to accomplish this without having to use a timer, COP instruction, or FFL.

Any Idea's for rung logic? I'm using RSLogix 5000.

I Would like to create an average of an analog signal. I have a transducer feeding a 4-20mA signal to my Analog input channel for current read out of a motor. The problem is the signal fluctuates a lot as the Current Transformer isn't really meant for such a low amperage.

It's a .75HP motor and it only draws at max 2.0 amps when running and the CT is for between 2-25A. The signal fluctuates a lot so It's difficult for the operator to read the running feedback on the HMI. So I'd like to average the current over 5 seconds to "Slow It Down".

Would like to know the easiest way to accomplish this without having to use a timer, COP instruction, or FFL.

Any Idea's for rung logic? I'm using RSLogix 5000.