Shifting an array in Logix 5000

- Thread starter shoelesscraig

- Start date

Similar Topics

Hey guys,

Again, another question I have that I can't seem to find the answer in the search.

I am writing a program to go along with my...

Greetings,

I am trying shift data in an array (such as Array[0] is shifted into Array[1], Array[1] is shifted into Array[2]......all...

Hello Guys,

I think I need to use SCL for the following task but am very weak using SCL in tia portal.

I have results history data block. It is...

Hey guys,

What do you suggest for doing a shift of dints within an array like this?

Thanks,

Kevin

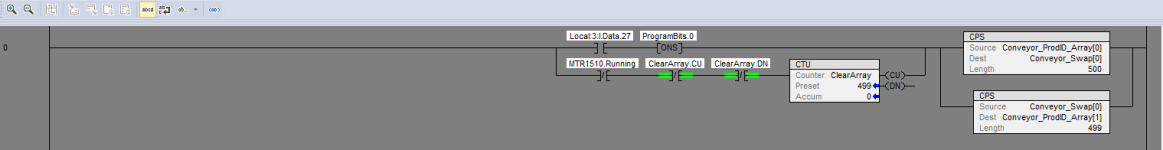

Not sure if this is possible but thought I would put it out there. Using Rockwell Studio 5000, is it possible to shift the address of an array...

![2020-05-29 00_13_15-RSLogix 5000 - T_PLC [1769-L32E 20.19]_ - [MainProgram - Data_Shift_].png 2020-05-29 00_13_15-RSLogix 5000 - T_PLC [1769-L32E 20.19]_ - [MainProgram - Data_Shift_].png](https://www.plctalk.net/data/attachments/47/47436-da5990870658d9f3d3974e4f76455639.jpg)