tewildrick

Member

1st post here, but have been lurking for months. I have found the threads here extremely helpful. I've been struggling with this issue for the last day or so and am at a loss for what is going on.

PLC: 5069-L340ERS2

Programmed in: Logix 5000 v32.11

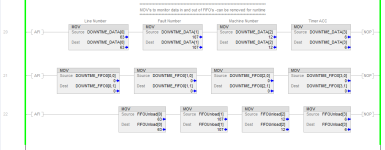

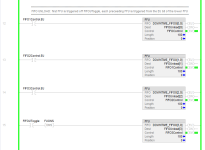

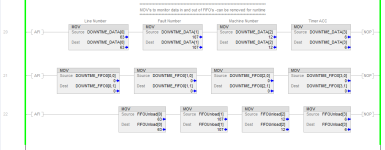

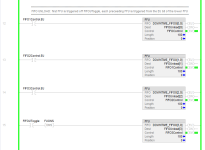

I'm using a FIFO to store downtime data for a production line. I am using a 4 DINT array to hold Line #, Fault #, Machine #, and Time in Seconds. I have a status tag that changes value depending on inputs from various photoeyes. If the value is not equal to 0 (meaning faulted) the "running time" information is placed in the array and a status change bit is triggered to load the FIFO. When the value goes back to 0 (running) the "downtime" gets loaded into the FIFO.

It seemed like a simple solution. Issue is that the downtime works but the runtime info is getting lost. I placed MOV's at the end of the routine to monitor the 4 DINTS, the FFL, and the 4 DINTS that the data is unloaded to and I can see the downtime values get loaded and unloaded but the uptime values aren't transferred from the array to the FIFO so its four zeros in and four zeros out.

Attached pics of the logic for reference.

PLC: 5069-L340ERS2

Programmed in: Logix 5000 v32.11

I'm using a FIFO to store downtime data for a production line. I am using a 4 DINT array to hold Line #, Fault #, Machine #, and Time in Seconds. I have a status tag that changes value depending on inputs from various photoeyes. If the value is not equal to 0 (meaning faulted) the "running time" information is placed in the array and a status change bit is triggered to load the FIFO. When the value goes back to 0 (running) the "downtime" gets loaded into the FIFO.

It seemed like a simple solution. Issue is that the downtime works but the runtime info is getting lost. I placed MOV's at the end of the routine to monitor the 4 DINTS, the FFL, and the 4 DINTS that the data is unloaded to and I can see the downtime values get loaded and unloaded but the uptime values aren't transferred from the array to the FIFO so its four zeros in and four zeros out.

Attached pics of the logic for reference.