online/offline vs. run/program

Ben,

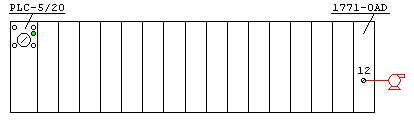

Obviously you have confused the PLC-5 platform with the newer ControlLogix platform. With the PLC-5 processors you MUST use a valid address (I repeat: ADDRESS) for your counters, etc. This is what Gerry was getting at. In ControlLogix you are allowed to just “make up” a tagname for the counter - but that won’t work with the PLC-5. Specifically, a PLC-5 counter will have an address such as “C5:0”. Now you ARE ALLOWED to give the counter’s address a “nickname” (something like COUNTER_1 would be acceptable) - and this “nickname” might LOOK LIKE a ControlLogix tagname - but in the PLC-5 system, the “nickname” MUST be tied to a valid existing address. The “nicknames” I’m referring to are called “SYMBOLS” in the PLC-5 family - which is what Gerry was referring to in his post.

Going just a little further - you CAN make online changes to the PLC-5 processor (as Vetteboy correctly pointed out) but even so there are some things that you can NOT do while the processor is actually RUNNING its program. For example: You cannot resize a data table file. Specific example: If your processor’s memory does NOT already have a C5:1 counter location assigned - then you cannot add that counter WHILE THE PROCESSOR IS RUNNING the program. For example: You would NOT be allowed to “accept” a new rung with the non-existent counter on it - since that operation would require resizing the counter data table file - to “make room for” the new counter. On the other hand, if you were to put the processor into the PROGRAM mode, then you WOULD be able to accept the new counter’s rung (assuming that the addressing syntax is correct). Of course putting the processor into the PROGRAM mode shuts down the plant and makes the boss very unhappy.

I’m bring these items up because you said you were going to be “reading up” and the RSLogix5 book has some errors in it. Take a look at:

Getting Results with RSLogix 5 Manual

On Adobe page 66 of 115 - or book page 56 - we find the following:

Online editing restrictions

During an online editing session you cannot:

resize data table files

create or delete program files

change program file protection

The first two restrictions are in error. With the PLC-5 processors, you CAN resize the data table files while ONLINE - and you CAN create or delete program files while ONLINE - but you CANNOT do these operations while the processor is actually RUNNING the program. You can change the program file protection (the third item) at any time.

Common source of confusion: The terms “ONLINE” and “RUNNING”.

The term “ONLINE” indicates that your programming computer is COMMUNICATING with the processor. Specifically, the term “ONLINE” has absolutely NOTHING to do with whether the processor is RUNNING the program or not.

The term “RUNNING” means that the processor is scanning the program rungs and trying to control its outputs. Now the processor might be ONLINE (communicating with your programming terminal while it’s RUNNING) - or it might be OFFLINE (not communicating with your programming terminal while it’s RUNNING). Secret handshake: The “online/offline/communicating” issue has ABSOLUTELY NOTHING WHATEVER to do with the “running/scanning/controlling” issue. Night and day. East and West. Completely separate issues.

Got that? Then don’t let what comes next confuse you. I'm including the following just for our many SLC users. Since you're using the larger PLC-5 family, the next part doesn't apply to you.

BUT - with the SLC family of processors, the restrictions listed above ARE CORRECT. With that particular (smaller) platform, in order to resize the data table files; create or delete the program files; or change the program file protection - you MUST go “OFFLINE” (specifically, you must STOP communicating with the processor) and make the necessary changes. Once the changes have been made, they must then be downloaded to the processor in order to take effect.

One more step and we’re finished. With the SLC-5/03, SLC-5/04, and SLC-5/05 processors, - (but NOT with the smaller SLC-500, SLC-5/01, and SLC-5/02 models) - you CAN make ONLINE changes to the program rungs - and the processor can actually be RUNNING its program too. Specifically, you can add and change the program rungs while the processor is RUNNING. More specifically, you do NOT have to shut down the plant just to change the rungs. It might help to think of a rung edit as a “minor” change. BUT - (with any SLC processor) - you still can NOT:

(1) resize data table files,

(2) create or delete program files, or

(3) change program file protection

while you are ONLINE (think: "communicating") with the processor.

Think of these as “major” changes to the processor’s memory structure. You’ve got to jump through some additional hoops to get these done.

Please post again if you have any other questions. I’m out of time for today.

Incidentally, the RSLogix software was originally written (as RSLogix500) for the SLC-500 family of processors. Later it was adapted (as RSLogix5) for the PLC-5 family. I have a hunch that the “book” errors I’ve listed above crept in while the documentation was being “cut and pasted” - and no one caught the differences between the platforms. And yes, I’ve reported these errors before.