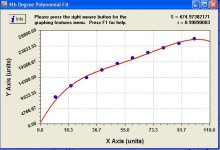

I need some controllogic code to create this flow curve

Been trying to figure out a way to do this is a clean and

accurate manner.

The analog input module is configured for 4-20 ma = 0-100 inches of H20

The physical calibrated flow measurements come out to this

0 0 LBM/H

10 8222 LBM/H

20 11628 LBM/H

30 14241 LBM/H

40 16444 LBM/H

50 18385 LBM/H

60 20140 LBM/H

70 21753 LBM/H

80 23255 LBM/H

90 24666 LBM/H

100 26000 LBM/H

as you can see even tho the 0-100 inches of h20 across

the orifice place is linear, the actual volume of material

is not. So I need a code snipit that can produce this curve.

Willing to compensate for the time, I need it by Monday Morning

Thanks

Been trying to figure out a way to do this is a clean and

accurate manner.

The analog input module is configured for 4-20 ma = 0-100 inches of H20

The physical calibrated flow measurements come out to this

0 0 LBM/H

10 8222 LBM/H

20 11628 LBM/H

30 14241 LBM/H

40 16444 LBM/H

50 18385 LBM/H

60 20140 LBM/H

70 21753 LBM/H

80 23255 LBM/H

90 24666 LBM/H

100 26000 LBM/H

as you can see even tho the 0-100 inches of h20 across

the orifice place is linear, the actual volume of material

is not. So I need a code snipit that can produce this curve.

Willing to compensate for the time, I need it by Monday Morning

Thanks