Hello all.

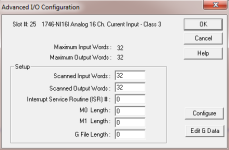

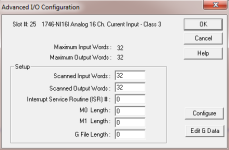

I have been working with an SLC 5/04 system, which houses various Digital and Analog INs and OUTs, up to Slot 29. I am currently mainly working with Slot 25, an Analog Input: 1746-NI16I. This is a system which has already been set up and has been running for the best part of 8-10 years. This particular card has had some spare inputs, one of which I am trying to connect to. In the Advanced Configuration, only a few Channels are actually "Enabled", and each channel is pretty much slightly different from another in terms of Input Type, Filter Frequency and Data Format. I am trying to set up Input 14, which is Channel 15, to "Enable" it, 4-20mA Input Type, Filter Frequency of 6 Hz and Data Format of either Raw/Proportional or Engineering Units.

Now, after I have made my choices, I click apply, and then OK. I am then confronted by a pop-up which states:

"Configuration Rung and Data

Integer Data File Number: 25

Integer Data Element: 100

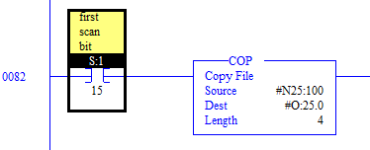

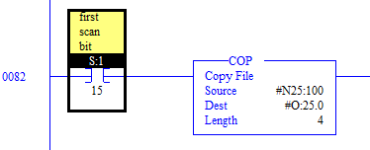

Rung to be inserted: XIC S2:1/15 COP #N25:100 #O0:25.0 24

At Program File Number: 4 82"

I have the options of OK or Cancel. If I click OK, I now have LAD 4, Rung 82 Highlighted. This First Scan Bit and COP function were already here, but does that mean I have now altered what is being written to "#O:25.0"? I now Download the Changes. However, after all this, I am not getting any Analog input reading coming in from the Live PLC.

What is this COP function? What does it do? How do I properly set up this Analog Card?

Thanks for your time,

-James

I have been working with an SLC 5/04 system, which houses various Digital and Analog INs and OUTs, up to Slot 29. I am currently mainly working with Slot 25, an Analog Input: 1746-NI16I. This is a system which has already been set up and has been running for the best part of 8-10 years. This particular card has had some spare inputs, one of which I am trying to connect to. In the Advanced Configuration, only a few Channels are actually "Enabled", and each channel is pretty much slightly different from another in terms of Input Type, Filter Frequency and Data Format. I am trying to set up Input 14, which is Channel 15, to "Enable" it, 4-20mA Input Type, Filter Frequency of 6 Hz and Data Format of either Raw/Proportional or Engineering Units.

Now, after I have made my choices, I click apply, and then OK. I am then confronted by a pop-up which states:

"Configuration Rung and Data

Integer Data File Number: 25

Integer Data Element: 100

Rung to be inserted: XIC S2:1/15 COP #N25:100 #O0:25.0 24

At Program File Number: 4 82"

I have the options of OK or Cancel. If I click OK, I now have LAD 4, Rung 82 Highlighted. This First Scan Bit and COP function were already here, but does that mean I have now altered what is being written to "#O:25.0"? I now Download the Changes. However, after all this, I am not getting any Analog input reading coming in from the Live PLC.

What is this COP function? What does it do? How do I properly set up this Analog Card?

Thanks for your time,

-James