I'll add to this, since I too am using Ignition and using some pretty complex recipes (~800 parameters across ~10 processes).

I had hoped to use the Recipe Module as TConnolly has mentioned, however it is considered an "MES" module and falls under the "MES" licensing structure. This eliminated the use of the recipe module for us as the number of "MES Tracking Points" that I would have required would have make Ignition extremely expensive. My evaluation is that the Recipe Module cost can only be justified if you are providing other "MES" functionality (at least for complex recipes). I will say the Recipe Module was really easy to use when I built my "proof-of-concept" system.

The alternate method was to "roll-my-own" which is extremely easy in Ignition; I had hope to find a solid "of-the-shelf" product, that's a side conversation.

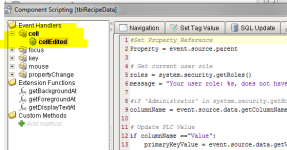

I use python scripting to "save/create/edit" my recipe, it's pretty simple scripting actually. My recipe editor is a table object, pointing to a "Recipe_Edit" table. Users directly edit the data in this table from the table object in Ignition. When saved, the data in the "Recipe_Edit" table is transferred into the "Recipe_Storage" table. This is the table where the run-time data is pulled when needed. The hard part of the design was creating proper tables in my database.

You must consider how you identify your recipes, part of my scripting is creating Universally Unique Identifiers (UUID), I don't rely on unique recipe names.

I differ from TConnolly on the transfer of data to the PLC. I am using transaction groups (TG) to download my recipe data. TGs provide better flexibly, are extremely quick, and I get handshakes to boot! When the PLC requires recipe data it triggers the TG, the TG queries the "Recipe_Storage" database and sends the data to the PLC.

TConnolly, I'm curious as to why you didn't use Transaction Groups?

This is my first project with Ignition as well, and it's by far the best/easiest SCADA package I have used and I'm producing the best "SCADA" project I've ever created due to the power of Ignition. I'm 100% sold on the platform ( but I still need a true recipe and batch solution, so they can do almost everything I need).