Hello All,

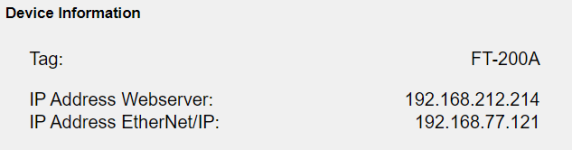

we have several ethernet IP promass 83 flowmeters from Endress + Hauser in our facility that we use to measure how much material we apply to each product going down the line. I am getting a "-1.#QNAN" input from one module for all the real inputs it provides. If im not mistaken, the NAN refers to "Not a Number." According to the PLC, the network connection is fine and dandy and not throwing any faults to the PLC. I am wondering if anyone has used these flowmeters before and seen anything similar. these are around 10 years old and were moved from a previous facility and those operations were brought here. I have also compared configuration files from a unit that is working via the web browser but nothing jumped out at me.

Thanks in advance,

L

we have several ethernet IP promass 83 flowmeters from Endress + Hauser in our facility that we use to measure how much material we apply to each product going down the line. I am getting a "-1.#QNAN" input from one module for all the real inputs it provides. If im not mistaken, the NAN refers to "Not a Number." According to the PLC, the network connection is fine and dandy and not throwing any faults to the PLC. I am wondering if anyone has used these flowmeters before and seen anything similar. these are around 10 years old and were moved from a previous facility and those operations were brought here. I have also compared configuration files from a unit that is working via the web browser but nothing jumped out at me.

Thanks in advance,

L