Mas01

Member

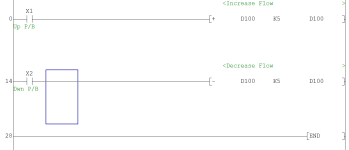

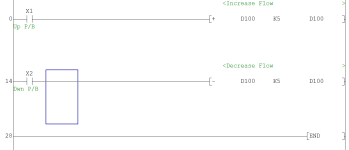

EDIT - just realised the push-buttons need to be "momentary contact" style.

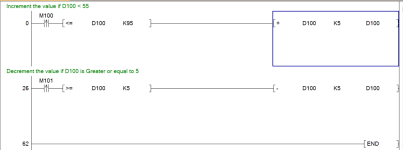

I think the code will look something like this.

Last edited:

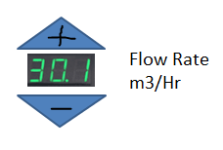

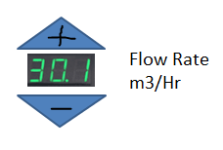

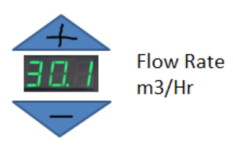

Brilliant, many thanks again for your input.Assuming you want to control it then yes it would need to send it out on an analogue output to a VFD. so for example, you have a VFD that is controlled from a 4-20ma from the PLC, your field can be adjusted we will say for 0-10 metres cubed per hour. the VFD would go from 0-50 Hz so assuming you want to alter the feed rate between 3-10 cm/h then your value will be adjustable from 3.0 to 10.0 (30 to 100 as an integer). then you need to scale this up so assume the analogue card requires a digital value of 0-2000 for 4-20ma then do the scaling in reverse as per the scaling of the analogue input.

So multiply the cm/h by 20 so at 5.0 cm/h = 1000 (12ma out of analogue card).

It will depend on the resolution you require i.e. 0.1 Cm/h or a higher one 0.01).

You will need to calibrate it somehow. i.e. run it at top speed for say a minute and weigh it. We used to do this on a rice process where the rice was fed continuously into a cooker, hot water & steam was injected as the rice moved along, perfect rice once calibrated, however, there was a lot of variables, rice Kg per hour, residence time, hot water addition in Kg/h, steam at Kg/h & auger speed.

Can't seem to find the LIBRARY window on my GTDesigner3...is it available from the main menu?Look at FA Metal Switch A2 under search by function you can add on top some text.

Edit: forgot to mention the text is a comment field not a text field, just associate a bit to the button.

I'm a bit confused by this: if I am controlling the flow from the PLC, I send the flow demand out on an analogue output card, but the confusing thing is...to actually read the value from the VFD in the first place, does it need connecting to an analogue input card?Assuming you want to control it then yes it would need to send it out on an analogue output to a VFD.