Bit_Bucket_07

Member

thank you soo much for your reply.

to answer ur question

1.version19

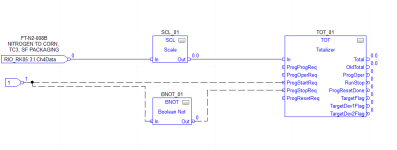

2.4-20ma flow rate,to be specific for totalizing natural gas we have fox thermal FT4A flow transmitter

please suggest how can i implement this as i have never done this and have no idea about it

I'd suggest that you consider a different instrument. I've used the Fox Thermal flow meters to totalize natural gas flow with both analog outputs and a pulse output connected to HSC modules. They worked fine -- for a while. We soon discovered that they would begin to behave erratically after several weeks of continuous operation when reading the pulse output for totalization. The only way to get them back to normal was to cycle the power to the instruments, then they'd work okay for another month or so.

We never could get a resolution to the problem via tech support. We sent multiple meters back to the factory for testing, and they were returned with no modifications and they still exhibited the same issues. These were connected to different PLCs and different power supplies and everything was installed according to specification. We finally just gave up on Fox Thermal and stopped using them altogether. Sorry to be the bearer of bad news.