Hi folks,

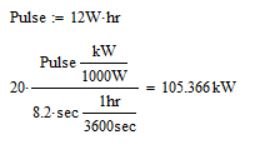

I'm getting pulses back from a recently installed meter and have found that when converting it to a rate it fluctuates quite a bit. I do realise that converting from a pulse to a rate is not going to be very accurate, I just expected it to be a little better than what it is. I've been monitoring the pulses themselves and it does look like the time between pulses varies slightly which explains why the rate is then fluctuating. This meter is monitoring our imported electricity usage and I know that the plant it is monitoring is running around 9.4MW. My readings are fluctuating from 9MW to 11.1MW which is a bit too inaccurate to do much with.

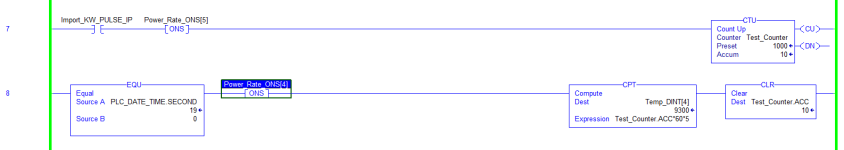

I've attached a sample of the code for one of the readings, it's quite simple at the moment but I may have to start filtering it. It is reading 9.3MW for the majority of the time which is great but it's the spikes up to 10.5MW or 11.1MW that are an issue.

I'm going to average the readings a bit and see if that makes much of a difference but I'm just wondering if there's another way of making this better that I'm not thinking of apart from averaging?

Also ... please don't rip me to shreds over not using UDT's in this example too... I know, I prefer them too but every time I download to this controller it fails to go back into run mode so modifying UDT's is a pain in the *** at the mo

I know, I prefer them too but every time I download to this controller it fails to go back into run mode so modifying UDT's is a pain in the *** at the mo  That's a problem for future Darren

That's a problem for future Darren

Thanks,

Darren

I'm getting pulses back from a recently installed meter and have found that when converting it to a rate it fluctuates quite a bit. I do realise that converting from a pulse to a rate is not going to be very accurate, I just expected it to be a little better than what it is. I've been monitoring the pulses themselves and it does look like the time between pulses varies slightly which explains why the rate is then fluctuating. This meter is monitoring our imported electricity usage and I know that the plant it is monitoring is running around 9.4MW. My readings are fluctuating from 9MW to 11.1MW which is a bit too inaccurate to do much with.

I've attached a sample of the code for one of the readings, it's quite simple at the moment but I may have to start filtering it. It is reading 9.3MW for the majority of the time which is great but it's the spikes up to 10.5MW or 11.1MW that are an issue.

I'm going to average the readings a bit and see if that makes much of a difference but I'm just wondering if there's another way of making this better that I'm not thinking of apart from averaging?

Also ... please don't rip me to shreds over not using UDT's in this example too...

Thanks,

Darren