harleymc100

Member

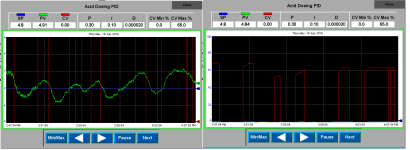

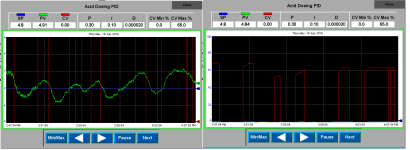

So a bit of background. We have a tank that pH corrects dairy waste water. We variably dose acid to keep it at a setpoint of pH 4.8 for optimum treatment.

Can any experts shed any light on our PID loop here?, As its not great.

We have cut the max pump speed to 65% to stop overshooting ( down) below setpoint, but my thoughts are, a properly tuned PID ? without the need to limit pump speed?

It doesn’t have to be perfect, it can bounce 0.5 above or below setpoint if needed.

Do the values entered here seem like they should work?

Can any experts shed any light on our PID loop here?, As its not great.

We have cut the max pump speed to 65% to stop overshooting ( down) below setpoint, but my thoughts are, a properly tuned PID ? without the need to limit pump speed?

It doesn’t have to be perfect, it can bounce 0.5 above or below setpoint if needed.

Do the values entered here seem like they should work?