AutomationTechBrian

Lifetime Supporting Member

The HMI is a re-branded Red Lion G315 (Eurotherm). The project is adding a small, inexpensive PLC, with a handful of discrete IO, and 2, 4-20 mA analog inputs to the machine. I need a separate PLC from the main SLC 5/05 because the machine runs 24 hrs a day, and this PLC will have the ability to be updated anytime, using my Stridelinx connection, without stopping the main PLC. It'll be used to control some of an ancillary machines that support the main machine, and bring alarms and feedback values into the HMI.

(Sidenote) This was my first, full HMI project, back in 2014. I chose the "Eurotherm" because most of the temperature controllers were Eurotherm, and the sales guy told me all the Eurotherm drivers were loaded and ready to go. If you're curious, here is the datasheet: https://www.eurotherm.com/?wpdmdl=28505 It's now an obsolete product. I have lots of history with this HMI on this board. While searching for answers, I found my first post on it here: http://www.plctalk.net/qanda/showthread.php?t=85953 ...coincidently, the topic is the same. I'm looking for the easiest way to add a new PLC using the existing drivers.

First, I tried adding a PLC I had in my shop... A (Koyo) Direct Logic 06. I spent a full day trying to get communication between the second com port on the DL and the HMI. I got a cable from Automation Direct with a 15-pin connector on one end, and bare leads on the other. I found someone who still and RJ12 blank plugs in stock, brought my breakout boards, then built and checked my cables for the correct RS232 configuration. The driver was K-sequence, and I used previous posts here that used pretty the same configuration. .....no luck! If I had unlimited time, and the customer wasn't located an hour-and-a-half away, I could probably figure it out. But the machine is down for service next week, and I have to fit this project in. I'm looking for simple, and not too expensive.

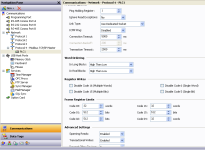

I called my local Rockwell sales/tech help and we worked out the a Micro 820 with an extra card for the AI would do the trick. It'll be available to pick up on Tuesday morning, if I still want it. I need to figure out if I can integrate it into the HMI without upgrading the HMI firmware... because the current Red Lion, 800-compatible firmware is probably not available for this re-branded, and obsolete, version of the G315.

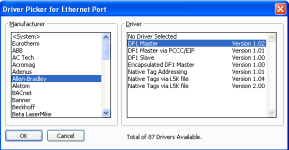

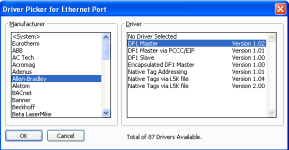

So, for you guys with experience, what do you think? What's the chance I can make a current Micro820 work with this 2014ish firmware, without turning it into another science experiment? I'd like to utilize the Ethernet connection if possible. If it needs to go RS232, the HMI uses an RJ12 port, so I'll probably have to build a cable. Below is a picture of the drivers listed on the HMI.

(Sidenote) This was my first, full HMI project, back in 2014. I chose the "Eurotherm" because most of the temperature controllers were Eurotherm, and the sales guy told me all the Eurotherm drivers were loaded and ready to go. If you're curious, here is the datasheet: https://www.eurotherm.com/?wpdmdl=28505 It's now an obsolete product. I have lots of history with this HMI on this board. While searching for answers, I found my first post on it here: http://www.plctalk.net/qanda/showthread.php?t=85953 ...coincidently, the topic is the same. I'm looking for the easiest way to add a new PLC using the existing drivers.

First, I tried adding a PLC I had in my shop... A (Koyo) Direct Logic 06. I spent a full day trying to get communication between the second com port on the DL and the HMI. I got a cable from Automation Direct with a 15-pin connector on one end, and bare leads on the other. I found someone who still and RJ12 blank plugs in stock, brought my breakout boards, then built and checked my cables for the correct RS232 configuration. The driver was K-sequence, and I used previous posts here that used pretty the same configuration. .....no luck! If I had unlimited time, and the customer wasn't located an hour-and-a-half away, I could probably figure it out. But the machine is down for service next week, and I have to fit this project in. I'm looking for simple, and not too expensive.

I called my local Rockwell sales/tech help and we worked out the a Micro 820 with an extra card for the AI would do the trick. It'll be available to pick up on Tuesday morning, if I still want it. I need to figure out if I can integrate it into the HMI without upgrading the HMI firmware... because the current Red Lion, 800-compatible firmware is probably not available for this re-branded, and obsolete, version of the G315.

So, for you guys with experience, what do you think? What's the chance I can make a current Micro820 work with this 2014ish firmware, without turning it into another science experiment? I'd like to utilize the Ethernet connection if possible. If it needs to go RS232, the HMI uses an RJ12 port, so I'll probably have to build a cable. Below is a picture of the drivers listed on the HMI.