You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Control Panel Pictures

- Thread starter CaseyK

- Start date

ndzied1

Lifetime Supporting Member

ndzied1

Lifetime Supporting Member

Eric Nelson

Lifetime Supporting Member + Moderator

Re: device names on covers

Like that's MY problem?...

Seriously though, I'd place the tags on the panel adjacent to the device, but that would require a larger enclosure just to accomodate the extra space needed for the tags. I use P-Touch labels for everything. As long as the surface is clean, they do NOT come off...

I see it all too often, but I frown of the practice of labeling the device itself. If someone replaces the device, there goes the label...

Great job, Norm! 'In progress' pictures are just as good... :nodi:

beerchug

-Eric

jdbrandt said:Wire cover (especially near the 'field wiring' is typically

removed during installation, and replaced after startup, if ever.

Similar lengths of wire cover can be interchanged, and the

labels don't line up. And, no, the end user people will NOT

take the time to make sure that all the right ones are in the

right places.

Like that's MY problem?...

Seriously though, I'd place the tags on the panel adjacent to the device, but that would require a larger enclosure just to accomodate the extra space needed for the tags. I use P-Touch labels for everything. As long as the surface is clean, they do NOT come off...

I see it all too often, but I frown of the practice of labeling the device itself. If someone replaces the device, there goes the label...

Great job, Norm! 'In progress' pictures are just as good... :nodi:

beerchug

-Eric

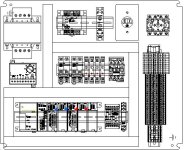

Here's an example of a small panel that is to be placed on a moving shuttle:

[attachment]

Notice how the Moeller isolator switch has a 90-degree angle to let the handle come out of the side of the panel.

And, there is a small fan at the top of the panel to aid in the convection cooling of the panel - A regular ventilator with an opening in the panel cannot be used as the intended location is extremely dirty.

About component labeling: Here in EU (allmost) all relay sockets, contactors, circuit breakers etc. have a detachable tab for putting the label. When exchanging a component you simply swap the tab.

[attachment]

Notice how the Moeller isolator switch has a 90-degree angle to let the handle come out of the side of the panel.

And, there is a small fan at the top of the panel to aid in the convection cooling of the panel - A regular ventilator with an opening in the panel cannot be used as the intended location is extremely dirty.

About component labeling: Here in EU (allmost) all relay sockets, contactors, circuit breakers etc. have a detachable tab for putting the label. When exchanging a component you simply swap the tab.

Eric Nelson

Lifetime Supporting Member + Moderator

How do you guys in Europe achieve such beautiful work? Every European made panel I've ever seen (and I've seen a LOT in my day!) is absolutely GORGEOUS!

I am SOOO jealous!...

beerchug

-Eric

I am SOOO jealous!...

beerchug

-Eric

Awwwww geee, Eric

It starts in the kindergaten: "Children, today we shall all try to layout a control panel. The best one will get a reward !"

Edit: For both small and big panels, our panel builders have a lot of say. They put the mounting plate on a table and take some time to layout all the components before attaching them permanently.

It starts in the kindergaten: "Children, today we shall all try to layout a control panel. The best one will get a reward !"

Edit: For both small and big panels, our panel builders have a lot of say. They put the mounting plate on a table and take some time to layout all the components before attaching them permanently.

Eric Nelson

Lifetime Supporting Member + Moderator

JesperMP said:It starts in the kindergaten: "Children, today we shall all try to layout a control panel. The best one will get a reward !"

Probably true!...

I think I'm going to start using galvanized DIN rail and panels. Maybe THAT'S the trick?...

beerchug

-Eric

Eric Nelson

Lifetime Supporting Member + Moderator

JesperMP said:Edit: For both small and big panels, our panel builders have a lot of say. They put the mounting plate on a table and take some time to layout all the components before attaching them permanently.

I do the same. I lay out everything in AutoCAD before drilling a single hole. Here's the layout of that heat staker panel:

[attachment]

But it STILL doesn't turn out NEAR as pretty...

beerchug

-Eric

ndzied1

Lifetime Supporting Member

Hey Eric,

Thanks for the Kudos but I wasn't the only one involved. The panels I posted were from my previous work and most things were a group effort.

One thing we did was to plot FULL SCALE drawings of the panel layout including mounting holes. The electricion would tape the drawings down on the panel and drill and tap all the mounting holes right through the drawing.

As long as the drawings were correct and plotted to the correct scale everything works very well!

nOrM

Thanks for the Kudos but I wasn't the only one involved. The panels I posted were from my previous work and most things were a group effort.

One thing we did was to plot FULL SCALE drawings of the panel layout including mounting holes. The electricion would tape the drawings down on the panel and drill and tap all the mounting holes right through the drawing.

As long as the drawings were correct and plotted to the correct scale everything works very well!

nOrM

Tom Jenkins

Lifetime Supporting Member

Similar Topics

I couldn't wait to kick off the less-than-pretty control panel thread! Sorry!

Here's a what happens when road salt meets a pull-box.

AK

- Replies

- 195

- Views

- 114,441

Hi,

If building a control panel in a 508a shop, when does it become a motor control center and fall out of scope for labelling under 508a?

More...

- Replies

- 1

- Views

- 385

I would like to get some feedback from the forum regarding control panel wiring and in particular segregation of wiring.

I happen to be part of a...

- Replies

- 3

- Views

- 850

Does anyone know of a good person/company that could troubleshoot an electrical problem in a control panel in South Carolina - tomorrow? If...

- Replies

- 9

- Views

- 2,201

I am very neurotic about control cabinet cleanliness. Unfortunately i have to convince my employer I nee to remove all of the precious spare...

- Replies

- 10

- Views

- 3,656