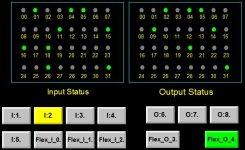

I hate making I/O status screens on my HMIs. As such, I usually only provide them if requested by my customer. In the past, I’ve entered these by hand and so they were tedious to make with lots of addresses and descriptions manually typed in. And then if I change or add/delete and I/O point, I have to remember to update the HMI project to match.

So I’m looking for an easier way.

So far the only thing I can come up with for MicroLogix and/or Compact/Controllogix platform with Panelview+ is to pass a parameter file to a “faceplate” that I build. I was thinking I could actually store the I/O descriptions in an array of strings and force or allow the user to enter them from the HMI. That way if an I/O point descripton changes, it is easy to update from the HMI instead of in the project.

Seems like there may already be some A/B faceplates for this but for the life of me I can’t figure out how to find them or what terms to even search for…

So how do you handle I/O status screens?

So I’m looking for an easier way.

So far the only thing I can come up with for MicroLogix and/or Compact/Controllogix platform with Panelview+ is to pass a parameter file to a “faceplate” that I build. I was thinking I could actually store the I/O descriptions in an array of strings and force or allow the user to enter them from the HMI. That way if an I/O point descripton changes, it is easy to update from the HMI instead of in the project.

Seems like there may already be some A/B faceplates for this but for the life of me I can’t figure out how to find them or what terms to even search for…

So how do you handle I/O status screens?