drbitboy

Lifetime Supporting Member

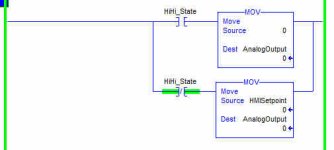

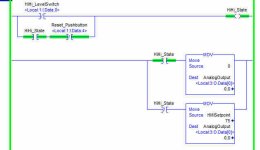

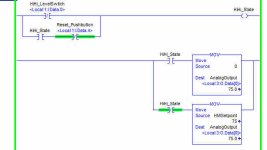

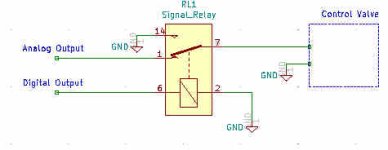

the operator has to write to something other than directly to the output itself, then logic can use the the alarm state (1 or 0) can choose whether that operator input, or 0, goes to the output to the valve. Look at post #7.

If the operator can only write to the valve output (Local:3:O.Ch0Data), then the logic that responds to the alarm condition should not copy that output unless that output is not 0; and perhaps it should only copy that output on the rising edge of the alarm condition.

If the operator can only write to the valve output (Local:3:O.Ch0Data), then the logic that responds to the alarm condition should not copy that output unless that output is not 0; and perhaps it should only copy that output on the rising edge of the alarm condition.

Last edited: