neokeelo

Member

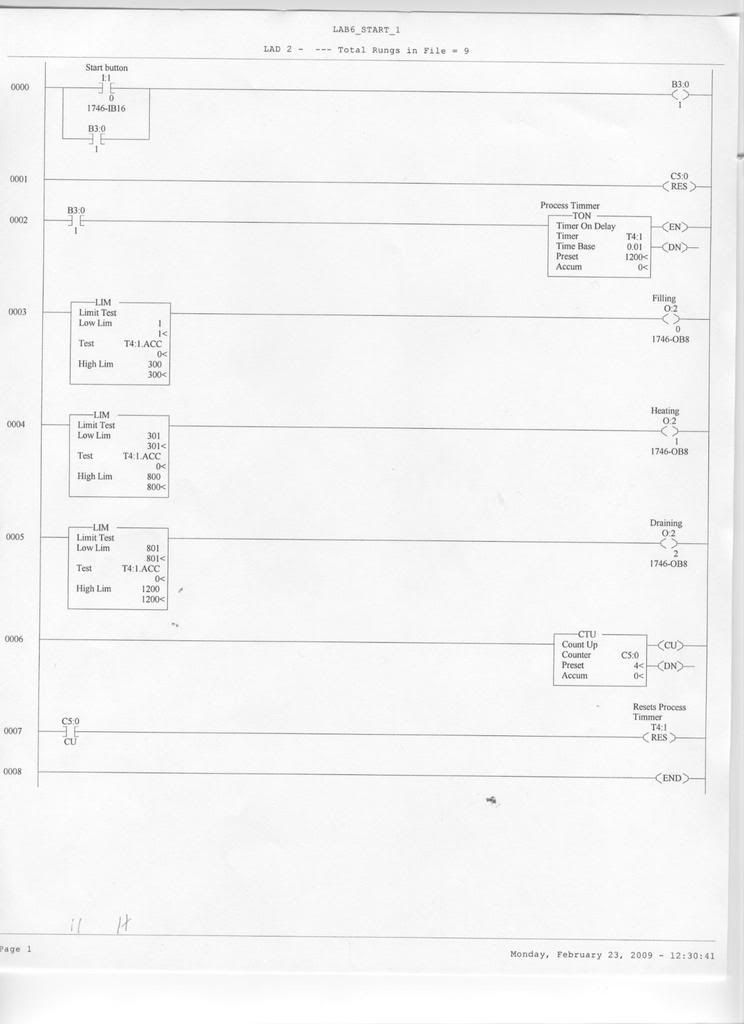

Hi. I am working on my 6th assignment. I have a better understanding of timers, counters, compare and the limit command but I am having trouble getting them to talk to each other.

Here is my program

-------------------------

Basically there are 3 process that need to run for a specified time, turn off and the next one start, repeat 4 times and stop and reset everything at the end.

Button one ( I:1/0) starts the process.

Filling = 3 secs O:2/0

Heating = 5 secs O:2/1

Draining = 4 secs O:2/2

Rules

I can use the comparison instructions and only one timer in the program. Also Only one counter can be used but not the counter DN bit.

Here is what I have so far. I know I need something on RUNG 6 but i dont know what. What am I missing to complete the program? Any advice is appreciated!

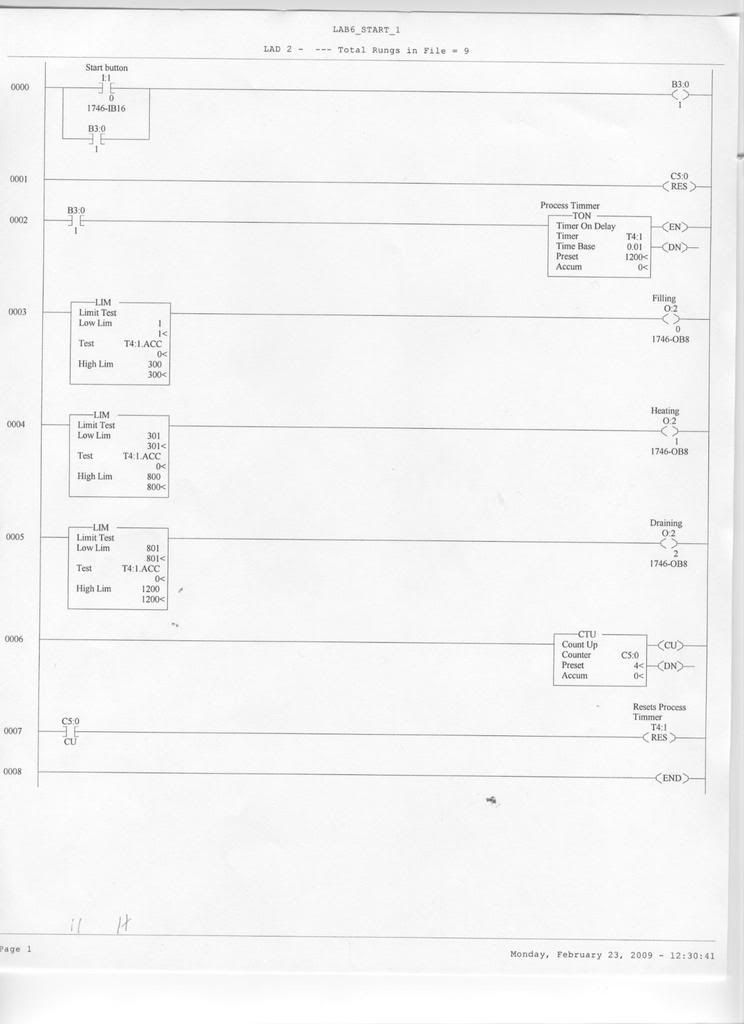

Here is my program

-------------------------

Basically there are 3 process that need to run for a specified time, turn off and the next one start, repeat 4 times and stop and reset everything at the end.

Button one ( I:1/0) starts the process.

Filling = 3 secs O:2/0

Heating = 5 secs O:2/1

Draining = 4 secs O:2/2

Rules

I can use the comparison instructions and only one timer in the program. Also Only one counter can be used but not the counter DN bit.

Here is what I have so far. I know I need something on RUNG 6 but i dont know what. What am I missing to complete the program? Any advice is appreciated!