JimSchmidt

Member

Good Day,

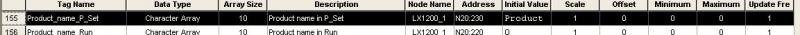

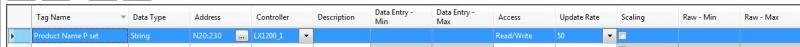

I have a PanelBuilder 32 application that is currently running on an old pv600 connected to a Micrologix 1200 that I'm trying to upgrade to a Panel View 800 using Connected Components Workbench. In the PBA file there are several tags that write characters to a N address. Tag properties go as follows: Tag Name= Product_name_P_Set, Data Type= Character Array, Array Size= 10, Node Name= LX1200_1, Address=N20:230, Scale= 1, Offset= 0, Min= 0, Max= 0, Update Fr=1

In the data file it places characters up to N20:235, however when i try this on the 800 it does not accept characters and will only write numbers in N20:230. It would seem to me that the correct thing to do is to have a string file that stores the information in the plc and the 800 will write properly to a string file but it would be nice not to have to re-program the plc.

I have a PanelBuilder 32 application that is currently running on an old pv600 connected to a Micrologix 1200 that I'm trying to upgrade to a Panel View 800 using Connected Components Workbench. In the PBA file there are several tags that write characters to a N address. Tag properties go as follows: Tag Name= Product_name_P_Set, Data Type= Character Array, Array Size= 10, Node Name= LX1200_1, Address=N20:230, Scale= 1, Offset= 0, Min= 0, Max= 0, Update Fr=1

In the data file it places characters up to N20:235, however when i try this on the 800 it does not accept characters and will only write numbers in N20:230. It would seem to me that the correct thing to do is to have a string file that stores the information in the plc and the 800 will write properly to a string file but it would be nice not to have to re-program the plc.