Hi All,

I'm translating an AB motion program (RSLogix 5000) to another PLC brand, and I need to reproduce a Cam profile.

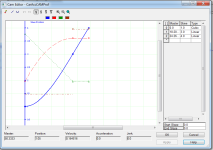

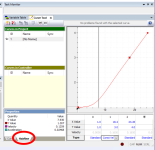

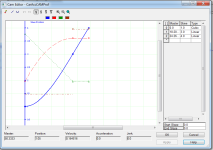

Please see attached "Cam Editor AB.PNG". This picture shows the Allen Bradley Cam Editor window. You will see the Master and Slave values (just 3 rows). The corresponding chart is the blue line.

For the new PLC, I need to provide all the Master points, from 0 to 25 (or 24). I could just look at the points in the Cam editor and manually write the values, but I would like to have a more efficient solution for future situations like this, and also learn about how to create cam profiles.

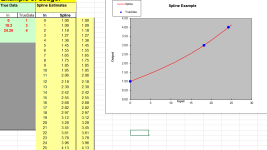

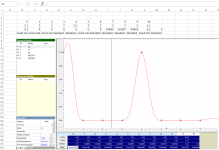

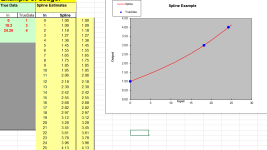

I downloaded an Excel spreadsheet with a spline formula, and got the interpolated values and chart as shown in attached picture "Excel Spline.PNG".

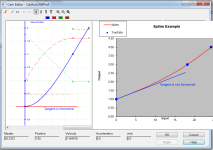

The problem is, at the beginning of the chart, I am not getting a smooth acceleration like with the AB Cam Editor. You can see that the Excel chart between 0 and 18.20 is almost a line, but in Cam Editor is more like a curve.

I noticed that the interpolation between the second and third point in Cam Editor (0 and 18.20) is defined as "Linear", but I don't see how to mimic that in Excel, I don't know how to trick formula by adding additional points to have a smoother start of the movement. I don't know if this is the reason for the different chart, though.

I'll appreciate you feedback. Be aware that I'm still in the process of learning about motion, so bear with me!

Thank you!

I'm translating an AB motion program (RSLogix 5000) to another PLC brand, and I need to reproduce a Cam profile.

Please see attached "Cam Editor AB.PNG". This picture shows the Allen Bradley Cam Editor window. You will see the Master and Slave values (just 3 rows). The corresponding chart is the blue line.

For the new PLC, I need to provide all the Master points, from 0 to 25 (or 24). I could just look at the points in the Cam editor and manually write the values, but I would like to have a more efficient solution for future situations like this, and also learn about how to create cam profiles.

I downloaded an Excel spreadsheet with a spline formula, and got the interpolated values and chart as shown in attached picture "Excel Spline.PNG".

The problem is, at the beginning of the chart, I am not getting a smooth acceleration like with the AB Cam Editor. You can see that the Excel chart between 0 and 18.20 is almost a line, but in Cam Editor is more like a curve.

I noticed that the interpolation between the second and third point in Cam Editor (0 and 18.20) is defined as "Linear", but I don't see how to mimic that in Excel, I don't know how to trick formula by adding additional points to have a smoother start of the movement. I don't know if this is the reason for the different chart, though.

I'll appreciate you feedback. Be aware that I'm still in the process of learning about motion, so bear with me!

Thank you!