Wrapping up the debugging and install for this system (been a pain with school and a local flood). I'm looking to limit the input values in the HMI based on current tag values. What is happening is when they enter some crazy number there is an overflow on the target device and values get overwritten.

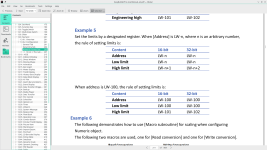

I'm using a numeric object with different read and write addresses. I saw that there is a dynamic limit, but I'm wanting there to be some notification for an invalid value.

Thanks again.

I'm using a numeric object with different read and write addresses. I saw that there is a dynamic limit, but I'm wanting there to be some notification for an invalid value.

Thanks again.