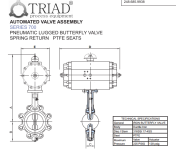

I'm wondering if you guys can help me decide the best way to go about controlling the level on a tank. I want to use a Pneumatic actuator and butterfly valve. The actuator has a 4-20 ma control signal to regulate the opening of the valve. The tank has a level sensor that will be used as a feedback to control the level.

I want to know if for this kind of application, I need to use a dedicated PID controller or can I used the PID function on a 1756-L62 CLX5562 controller.

Ask questions please if I have not being clear enough on what I'm trying to do.

I want to know if for this kind of application, I need to use a dedicated PID controller or can I used the PID function on a 1756-L62 CLX5562 controller.

Ask questions please if I have not being clear enough on what I'm trying to do.