Due to a couple of electric shocks, my company began fitting RCDs to field inputs to PLCs.

Generally, it was one RCD per PLC card with either 8 or 16 inputs, these were either push buttons, limit switches, PE sensors or inductive proximity sensors.

Voltage was 240V AC.

The problem - The RCDs frequently trip out.

Has anyone here fitted RCDs to PLC inputs before, and if so, what was your experience? Are there any common problems that you have to be wary of?

Back ground.

We have an old site with plant dating from the 40's to newly installed systems. All new systems are specified with a control voltage of 24V DC, however all our old plant (about 80%) is wired with our old standard of 240V AC. We have recently had a few incedence of electric shock (Luckyly only minor boots) from operators touching damaged sensors or worn insulation. To be fair to the operators, the damage isn't always obvious, and the contact is not always intentional.

It was deemed too expensive to convert all systems to 24V DC, so as an alternative, it was decided to fit RCDs to the 240V sensors. This job has just begun, and the first RCDs are frequently tripping.

I was brought on board with this proble this morning, but the guys who are handling the installation are on shift and won't be back until Monday.

So far, I have come up with the following possibilities.

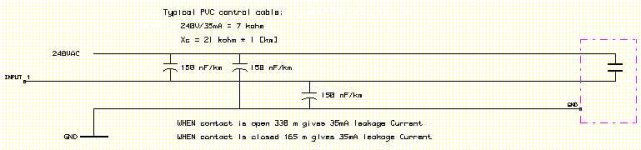

1, PLC inputs out of the RCD loop. Enough inputs come on and the current inbalance exceeds 35mA, tripping the circuit.

2, Leakage from the PLC input card.

3, Leakage due to harmonics.

If there is any thing else that I should check, please let me know.

I have to wait until Monday before starting, but it's good to get some advanced ideas.

Thanks,

Doug

Generally, it was one RCD per PLC card with either 8 or 16 inputs, these were either push buttons, limit switches, PE sensors or inductive proximity sensors.

Voltage was 240V AC.

The problem - The RCDs frequently trip out.

Has anyone here fitted RCDs to PLC inputs before, and if so, what was your experience? Are there any common problems that you have to be wary of?

Back ground.

We have an old site with plant dating from the 40's to newly installed systems. All new systems are specified with a control voltage of 24V DC, however all our old plant (about 80%) is wired with our old standard of 240V AC. We have recently had a few incedence of electric shock (Luckyly only minor boots) from operators touching damaged sensors or worn insulation. To be fair to the operators, the damage isn't always obvious, and the contact is not always intentional.

It was deemed too expensive to convert all systems to 24V DC, so as an alternative, it was decided to fit RCDs to the 240V sensors. This job has just begun, and the first RCDs are frequently tripping.

I was brought on board with this proble this morning, but the guys who are handling the installation are on shift and won't be back until Monday.

So far, I have come up with the following possibilities.

1, PLC inputs out of the RCD loop. Enough inputs come on and the current inbalance exceeds 35mA, tripping the circuit.

2, Leakage from the PLC input card.

3, Leakage due to harmonics.

If there is any thing else that I should check, please let me know.

I have to wait until Monday before starting, but it's good to get some advanced ideas.

Thanks,

Doug