Karac

Member

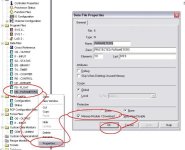

I'm currently upgrading a program in a Micrologix 1100 using RSLogix 500; the program currently uses about a dozen variables set by the operator to set limits on some minimum and maximum acceptable analog values. My problem is that whenever I download a new ladder program I have to write down these values because downloading overwrites them. Is there an option or method to download just the program and not the old data stored in my laptop, or a way to suck the current values in the PLC into my new ladder?

This isn't an insurmountable problem yet, there's only a dozen or so variables I have to write down on a sheet of paper and re-enter. But over the next week or so, that numbers going to go up to over a hundred, becoming at the least a massive pain.

If I'm not being clear, this can be done in DirectSoft 5; there's a choice there to send over the new 'program' (just the ladder logic, keeping the current variables), or sending the 'project' (sending the new ladder logic and the variables in my laptop to the plc).

This isn't an insurmountable problem yet, there's only a dozen or so variables I have to write down on a sheet of paper and re-enter. But over the next week or so, that numbers going to go up to over a hundred, becoming at the least a massive pain.

If I'm not being clear, this can be done in DirectSoft 5; there's a choice there to send over the new 'program' (just the ladder logic, keeping the current variables), or sending the 'project' (sending the new ladder logic and the variables in my laptop to the plc).