Long time reader first time poster.

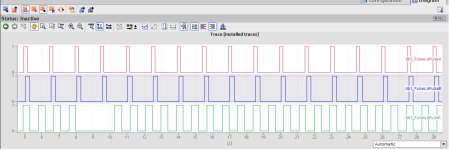

I have the following pulse signals as attached generated by an OEM machine.

I am aiming to recreate the waveforms in order to test another program I have developed as an add on. The top 2 wave forms (product holders) are constant on the machine. The bottom wave(represents a product present in the holder) is more likely to be high or low.

I have created some logic with a myriad of timers and set bits but it is not robust IMO or constant. It would probably do for testing tbh, but this has me thinking surely there is a better way.

I have looked at enabling the system and memory bytes as a clock but it is constant, can it be manipulated?

I'm looking some inspiration and direction to reach a half decent solution.

I have the following pulse signals as attached generated by an OEM machine.

I am aiming to recreate the waveforms in order to test another program I have developed as an add on. The top 2 wave forms (product holders) are constant on the machine. The bottom wave(represents a product present in the holder) is more likely to be high or low.

I have created some logic with a myriad of timers and set bits but it is not robust IMO or constant. It would probably do for testing tbh, but this has me thinking surely there is a better way.

I have looked at enabling the system and memory bytes as a clock but it is constant, can it be manipulated?

I'm looking some inspiration and direction to reach a half decent solution.