I have a PID in a SLC 500 that does not function as it should. Have deleted it remade it and still have a problem also moved it up and down in the ladder.

It reads a temperature sensor, the signal is good and has been calibrated.

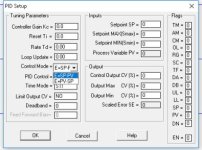

I have a set point of 195, my process value is always on 2 no matter how you set the PID up. I have a cooling PID with the same Integer bit as the heat and it works as it should. These two PID's control a 3 way valve that calls for heat and cool of an oil heater. Has anyone ran into this before?

It reads a temperature sensor, the signal is good and has been calibrated.

I have a set point of 195, my process value is always on 2 no matter how you set the PID up. I have a cooling PID with the same Integer bit as the heat and it works as it should. These two PID's control a 3 way valve that calls for heat and cool of an oil heater. Has anyone ran into this before?