Hi all,

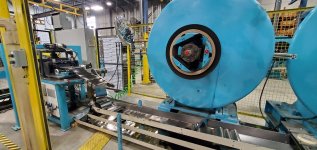

I'm looking for ideas on how to program the control of the payout of my uncoiler. The machine has a servo-driven feeder that feeds material about every 10-15 seconds. The feeds vary in length. The material is uncoiled into trays and the feeder draws from these trays. You can think of the trays as accumulators for the material.

Currently, I measure the radius of the coil on the uncoiler. I have a prox that triggers on 8 evenly spaced bolts around the drum (I also have an encoder on the uncoilers) Using the measured diameter I calculate how much material there is between each prox pulse. I have a "Fed_Material" tag in the PLC that represents the amount of material in the tray. Every time the prox pulses I add the calculated amount to the tray. Every time the feeder does a feed I subtract the feed amount from the tray.

The feeder will wait until there is enough material in the tray before feeding. The uncoiler compares what's in the tray and what's needed for the next feed. If the next feed is greater than what's in the tray, the uncoiler will begin to accelerate. If the the tray has more then then the next feed, the uncioler will slow down. The idea is to keep the uncoiler turning continuously. As the tray gets low the uncoiler speeds up but if it gets to full the uncoiler slows down.

This works ok but I would like to know what you guys have come up with.

Thanks

Shane

I'm looking for ideas on how to program the control of the payout of my uncoiler. The machine has a servo-driven feeder that feeds material about every 10-15 seconds. The feeds vary in length. The material is uncoiled into trays and the feeder draws from these trays. You can think of the trays as accumulators for the material.

Currently, I measure the radius of the coil on the uncoiler. I have a prox that triggers on 8 evenly spaced bolts around the drum (I also have an encoder on the uncoilers) Using the measured diameter I calculate how much material there is between each prox pulse. I have a "Fed_Material" tag in the PLC that represents the amount of material in the tray. Every time the prox pulses I add the calculated amount to the tray. Every time the feeder does a feed I subtract the feed amount from the tray.

The feeder will wait until there is enough material in the tray before feeding. The uncoiler compares what's in the tray and what's needed for the next feed. If the next feed is greater than what's in the tray, the uncoiler will begin to accelerate. If the the tray has more then then the next feed, the uncioler will slow down. The idea is to keep the uncoiler turning continuously. As the tray gets low the uncoiler speeds up but if it gets to full the uncoiler slows down.

This works ok but I would like to know what you guys have come up with.

Thanks

Shane