locotumbler

Member

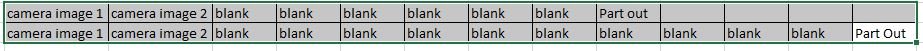

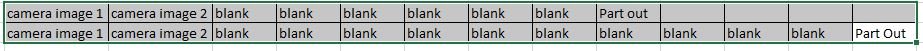

I have a camera system in a die that I am writing the program for.

I have two tracks and capture two consecutive parts.

The part out locations are 8 and 12 stations after my earliest parts in each track respectively.

I move a 1 (good) or 0 (bad) into the source location for the FIFO stack. on the next progression.

If the part had a good image at the first image it can fail a different measurement on the next station. Am I able to move a zero into the start of the FIFO stack after the source bit has been loaded in? Or would I be better off:

1. Running two seperate FIFO stacks and having my retraction output looking for both of the fifo unload bits to be positive

2. move the 0 into a different bit then move it into the position after the fifo stack stack start. I have proven that I can move the bit into N7:29 without an issue and have it remain through the FIFO sequence.

Please see the attached code. and mock of what i mean with the lanes.

I have two tracks and capture two consecutive parts.

The part out locations are 8 and 12 stations after my earliest parts in each track respectively.

I move a 1 (good) or 0 (bad) into the source location for the FIFO stack. on the next progression.

If the part had a good image at the first image it can fail a different measurement on the next station. Am I able to move a zero into the start of the FIFO stack after the source bit has been loaded in? Or would I be better off:

1. Running two seperate FIFO stacks and having my retraction output looking for both of the fifo unload bits to be positive

2. move the 0 into a different bit then move it into the position after the fifo stack stack start. I have proven that I can move the bit into N7:29 without an issue and have it remain through the FIFO sequence.

Please see the attached code. and mock of what i mean with the lanes.