Good afternoon all.

I've been tasked in getting a 2711R-T4T PanelView 800 4.3” communicating with a AB SLC5/03 PLC.

This was a system which was working in the past with another HMI (which stopped working) and the 2711R-T4T PanelView 800 4.3” is its replacement.

The top channel 1 RJ45 port is used for comms with an Intouch Scada network.

So I will be using the bottom Channel 0 RS232 port for comms with the panelview.

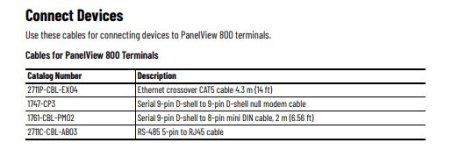

Before I go to site and investigate, I want to check about the correct cable.

I have the following two cables and wondering if they are suitable.

1. 1756CP3/A I'm pretty sure this cable is ok, but its my own programming cable and I need it.

2. 1761 CBL-AC00 SER.A AIC To Controller Comms Cable, very short but may work.

Any help or advice would be greatly appreciated.

Regards Padraic.

I've been tasked in getting a 2711R-T4T PanelView 800 4.3” communicating with a AB SLC5/03 PLC.

This was a system which was working in the past with another HMI (which stopped working) and the 2711R-T4T PanelView 800 4.3” is its replacement.

The top channel 1 RJ45 port is used for comms with an Intouch Scada network.

So I will be using the bottom Channel 0 RS232 port for comms with the panelview.

Before I go to site and investigate, I want to check about the correct cable.

I have the following two cables and wondering if they are suitable.

1. 1756CP3/A I'm pretty sure this cable is ok, but its my own programming cable and I need it.

2. 1761 CBL-AC00 SER.A AIC To Controller Comms Cable, very short but may work.

Any help or advice would be greatly appreciated.

Regards Padraic.