It looks like itÂ’s time for a total redesign and rebuild

The inevitable "throw it all away, garbage!" response, there's always one of those

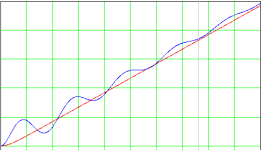

I agree with everyone who has said PWM with a DC actuator would be a more controllable solution. The thing is, if there were no massive load cell overshoot due to the high accel/decel, it would be easy to use the SSR solution and have it stop within the original tolerance range I stated at the beginning, even with the cycle time and zero-crossing delays. I would argue that not forseeing this was probably the thing that wasn't done correctly. A smooth load cell response would mitigate most of the issues here.

Unfortunately a DC actuator would have meant a 15+ Amp DC power supply, additional enclosure cooling, and a larger enclosure. Based on those trade-offs, the decision was made to use an AC actuator. Right or wrong, it's what I'm dealing with.

The motor is built-in to the actuator, so retrofitting a stepper isn't an option.

I'm also not convinced that a PLC is too slow for this.

I can make this system work by simply inching for 30ms, wait for 1 second, 30ms on, wait, etc. until within the tolerance range. Or 50ms. Or 70ms. It would work, but take longer to reach the setpoint, and would be a bit of a crude solution. I was hoping there might be a better way to implement smoother motion with the existing actuator, ideally programmatically.

I think the mentions of using a VFD or similar are on the right track for the AC actuator, just not sure how this would work as the actuator is single-phase (how do you reverse it?). And the extend/retract leads are separate, this is phase-neutral. Ramping up and down the current to the actuator seems to me that it would provide the smoothest motion without the load cell dynamics issues, as Jesper mentioned.

Think using single-phase electronic soft-starters with on-off control might work within the spec'd tolerances?

Thanks again everyone for the input.