Hello everyone,

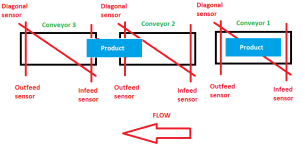

I am in charge of programming a handling system that includes conveyors, cranes, saw, ... on PLC Allen Bradley 1756-L8, and I have to program Data Tracking to tack each product at any time

I will create an instance of the UDT for each conveyor, and when product is moved from one station to another, the data is copied to the next station.

Every thing seems straight forward when it's in automatic mode and the system is running smooth

My 3 questions today are about monitoring this Tracking:

1- Do you think that transferring data from one station to another is triggered by SFC step or conveyor sensors? what about if operator starts conveyors in manual mode where the SFC is frozen or even reset to the initial step??

2- Do you think it is important to create an intermediate Tracking UDT between the two conveyors, so when the product is being transferred to the next conveyor the data is transferred to an intermediate UDT and when the transfer is finished, the data is sent to the destination station UDT??

3- What about Recovering from an Estop, SFC Reset, what are the best practices to handle the Data Tracking especially if conveyors are moved manually by the operator?? I must avoid data shift or loss

I thank you in advance

I am in charge of programming a handling system that includes conveyors, cranes, saw, ... on PLC Allen Bradley 1756-L8, and I have to program Data Tracking to tack each product at any time

I will create an instance of the UDT for each conveyor, and when product is moved from one station to another, the data is copied to the next station.

Every thing seems straight forward when it's in automatic mode and the system is running smooth

My 3 questions today are about monitoring this Tracking:

1- Do you think that transferring data from one station to another is triggered by SFC step or conveyor sensors? what about if operator starts conveyors in manual mode where the SFC is frozen or even reset to the initial step??

2- Do you think it is important to create an intermediate Tracking UDT between the two conveyors, so when the product is being transferred to the next conveyor the data is transferred to an intermediate UDT and when the transfer is finished, the data is sent to the destination station UDT??

3- What about Recovering from an Estop, SFC Reset, what are the best practices to handle the Data Tracking especially if conveyors are moved manually by the operator?? I must avoid data shift or loss

I thank you in advance