thanks for info. been under the weather so just now checking forum.

what we looking at experimenting with is a x,y,z type table that we may build out of aluminum.

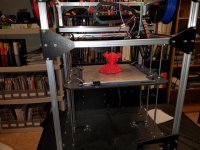

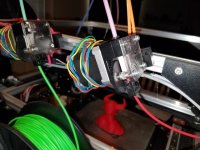

From what I can tell a 3d printer that you can get kits for use Arduino and Ramp1.4 type boards and controls. Actually see a lot of youtube videos showing how to actually hook everything up and the software packages.

One that I got the most sense out of showed downloading what was called Marlin Firmware for RepRap 3D printers based on the Ardunio platform. Then opened a STL file with SLIC3r to generate G code and then streamed the G code to the Arunino using a software package called Pronterface.

Instead of actually using a extrusion head to feed filament what I am looking at doing is mounting a hot melt type extruder head from a floor mounted ball screw type extruder and when you start to print the pattern of glue, etc. the x,y,z table follow the path defined in the G code file. Not sure if I will ever get it built because of the weight of the glue nozzle head is about 5 lbs plus a hose from the tank that pellets are fed into and head and extruded out through the glue head. looks like if I could find a kit that used Nema 34 size stepper motors I might be able to get something going just to test a theory.

Will actually use a Allen Bradley PLC to feed material in etc that needs to have what I refer to as the 3D printer and start the application of the glue type material and once done exit that one and feed in more material. Anyone ever seen something like this done. Thanks