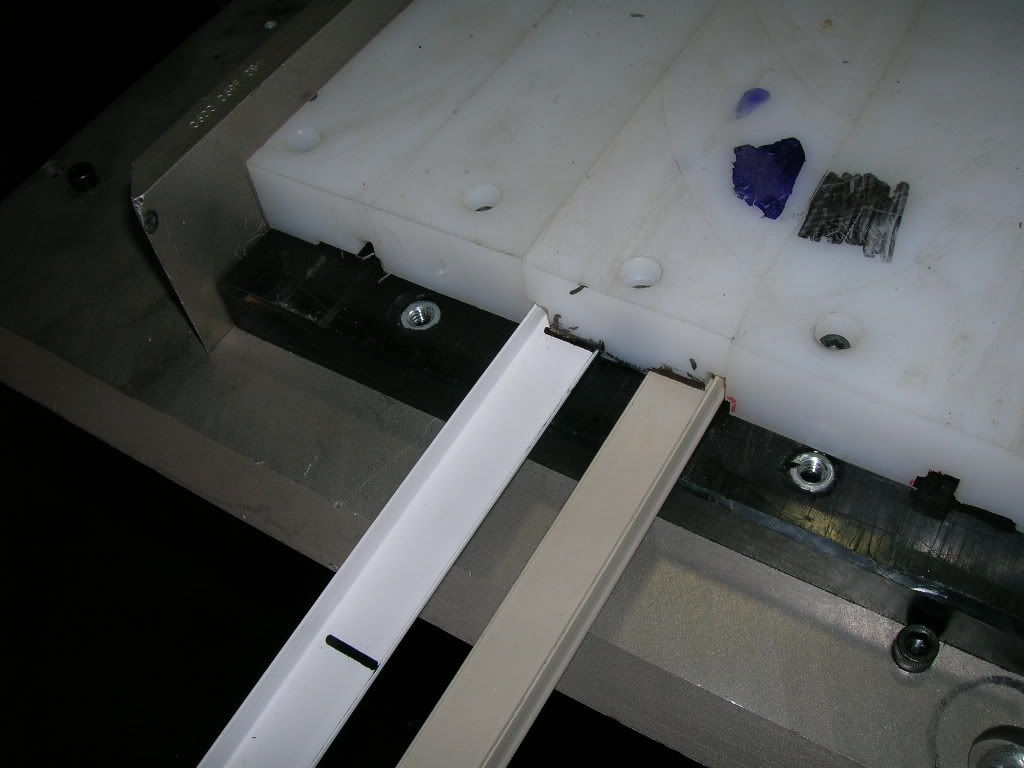

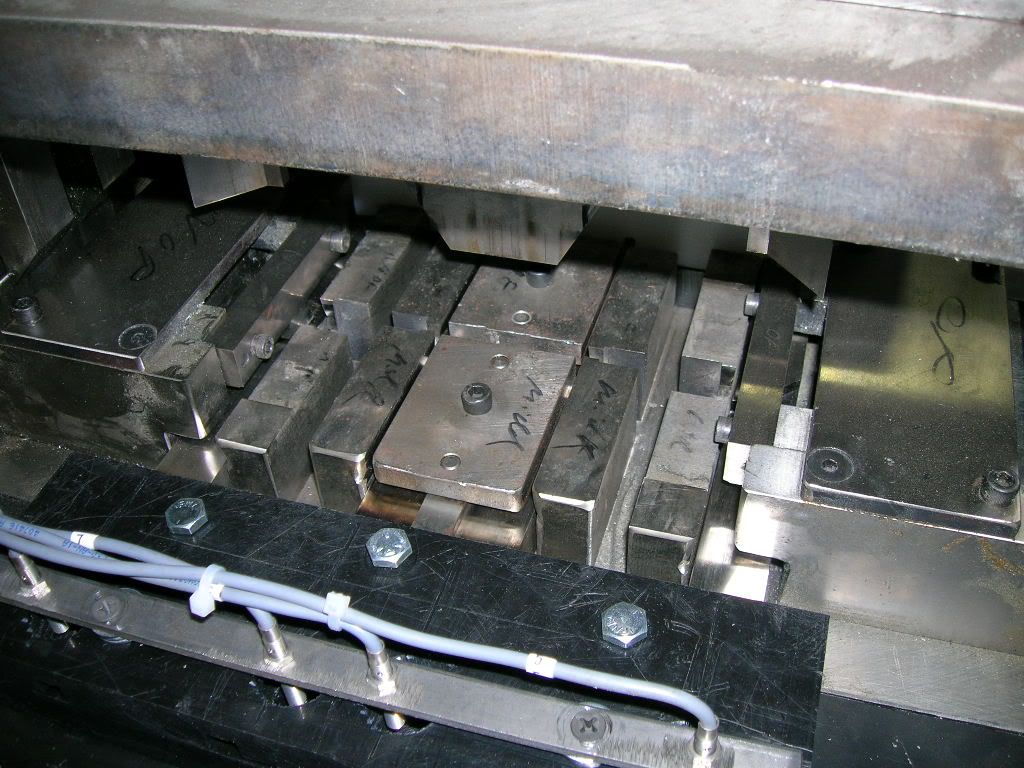

The material is an "L" shaped piece of PVC vinyl. It is about .051" thick, .770" wide, and the "L" leg is about .355" high. The raw piece is 18' long. It is the piece installed around the glass on a vinyl window. The punch we are using has 4 stations, 2 of which are used at the same time. Each "pair" of stations process the piece slightly different. The inner 2 stations cut the pieces at a straight 90 degrees. The outer 2 stations cut the pieces at a 45 degree angle and notch 1/8" from the "L" dogleg. They use all 4 peices on each window sash.

The punch was an existing unit in the plant that I am attempting to automate. I have a 3" polyurethane roller with polyurethane pinch wheels to feed the parts through the punch. I see the logic behind having the encoder mounted separately from the the drive roller. Do you think that mounting it to the pinch rollers is a good idea? There isn't alot of room for an extra roller in there. I currently have it mounted on the drive roller.

I'll try to take a couple of pictures today of the setup that we have to give you a better idea of what is going on.

I hope that my explainations are clear enough. I am not the best technical writer in the world.

The punch was an existing unit in the plant that I am attempting to automate. I have a 3" polyurethane roller with polyurethane pinch wheels to feed the parts through the punch. I see the logic behind having the encoder mounted separately from the the drive roller. Do you think that mounting it to the pinch rollers is a good idea? There isn't alot of room for an extra roller in there. I currently have it mounted on the drive roller.

I'll try to take a couple of pictures today of the setup that we have to give you a better idea of what is going on.

I hope that my explainations are clear enough. I am not the best technical writer in the world.

Last edited: