Yes, if you are careful! An error here can cause unpredictable results!

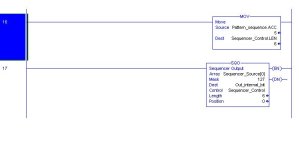

I think it would be smarter to move the Position. If Position = 0, then Move 1 to Position. This will skip over the Position 0. Then you do not have to worry about changing the Length. Notice that changing Len from 6 to 5 will NOT delete the Start Position 0.

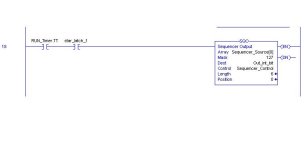

You could skip Position 0 by adding a parallel branch on Rung 18, in parallel with the TT Timer contact, to check if Position = 0, and if true, then trigger SQO to move from Positon 0 to Position 1.

I would not use a TT timer bit to trigger the SQO. Notice that this only works when TT goes on for 15 minutes, then off. The SQO is only triggered when TT goes to OFF at the end of the 15 minutes. Normally a Timer DN bits works better. If the timer is self-resetting, DN is only ON for 1 PLC scan.

Another way to handle the Position 0 problem is to put a Comparison on the timer trigger, so that if System is in RUN mode, and SQO position = 0, then trigger 1 timer cycle (reset the timer 1 time), causing a skip of the SQO from Position 0 to Position 1.