dbh6

Lifetime Supporting Member

Hello all,

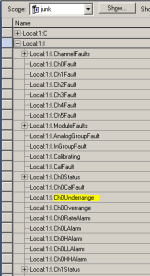

I so happen to be working with a program that has a AB 1756-IF6I, analog input module. I noticed that once you right click on the module in the IO configuration in the controller organizer and select properties it has couple of tabs, one of them which is the configuration tab that has input parameters for the scaling for the High/Low signals in ma and also the High/Low engineering values.

From the process that i'am working on, we have a lot of pressure transducers that are sending a 4-20ma signal as an input to the channels on the 1756-IF6I module.

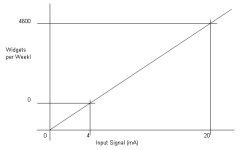

So my question arises, since this module already has set point parameters for your scaling, would this omit the need to use scaling calculations in your logic? Ex. if you put 20ma as the high signal and 4 ma for the low signal and have high / low engineering scaled values of 100 & 0(representing PSI) would the 4-20ma signal correctly scale an output value between 0-100 PSI depending on what the 4-20 signal is?

Lastly their is an input range where you specify what kind of signal is coming in, in my case i selected the 0ma to 20ma as that is the only option for for a ma signal. So since 0ma to 20ma is the only option, then when you enter your scaling values for the High /Low signals should the low signal be 0ma or 4ma? because if i use 4ma then how will we be able to differentiate Ex. from a broken wire when the ma signals drops below 4ma? and if we choose 0ma as our low signal then our scaling won't work correctly because the pressure transducer is sending a 4-20 not 0-20, maybe play with the Sensor offset parameter???

If someone can clear this up, i would appreciate it, btw plc is a control logix with 1756 L62 CPU.

I so happen to be working with a program that has a AB 1756-IF6I, analog input module. I noticed that once you right click on the module in the IO configuration in the controller organizer and select properties it has couple of tabs, one of them which is the configuration tab that has input parameters for the scaling for the High/Low signals in ma and also the High/Low engineering values.

From the process that i'am working on, we have a lot of pressure transducers that are sending a 4-20ma signal as an input to the channels on the 1756-IF6I module.

So my question arises, since this module already has set point parameters for your scaling, would this omit the need to use scaling calculations in your logic? Ex. if you put 20ma as the high signal and 4 ma for the low signal and have high / low engineering scaled values of 100 & 0(representing PSI) would the 4-20ma signal correctly scale an output value between 0-100 PSI depending on what the 4-20 signal is?

Lastly their is an input range where you specify what kind of signal is coming in, in my case i selected the 0ma to 20ma as that is the only option for for a ma signal. So since 0ma to 20ma is the only option, then when you enter your scaling values for the High /Low signals should the low signal be 0ma or 4ma? because if i use 4ma then how will we be able to differentiate Ex. from a broken wire when the ma signals drops below 4ma? and if we choose 0ma as our low signal then our scaling won't work correctly because the pressure transducer is sending a 4-20 not 0-20, maybe play with the Sensor offset parameter???

If someone can clear this up, i would appreciate it, btw plc is a control logix with 1756 L62 CPU.