Paul,

off-topic but:

I'm about to go down the G306K route and would appreciate any thoughts as to comparing the 306 with a PVplus 600.

Refresh rates, image looks, stuff like that.If you don't mind posting here great, otherwise send me a pm.

I know it's not an apples to apples comparison but it will help me a lot pulling the trigger.

Software isn't an issue,I have been playing with crimson 3.0 for a few days and looks good.

Thanks,

BK.

I am new to them but here's my first thought's on your comparison, since we burn through a lot of PV+600's here.

The PV+600 has ethernet, where my Kadet has dual serial in a single D-Sub 9 pin male right on the bottom. Think right angle hood (backshell) if you mount it directly above something.

The Kadet looks like a much better built device than the PV+. My 8 page 100 tag application for my ~$350 four inch is up and running in 7 seconds after I switch on the power.

SPeaking of power, Crimson 3.0 is rude and clean. It doesn't have some of the pre configured settings you'll find in the PV+ and some other HMIs, but it does offer a very powerful raw, open, and flexible command language that appears to have awesome potential.

Crimson 3.0 is like a full box of hand tools and huge variety of nuts and bolts, and the FactoryTalk View Based PV+ is more like a few shelves of power tools, some with missing chuck keys, and arcing brushes.

The boot time of the Kadet alone would pay for them on our patty forming machines, because they get powered down and locked out for adjustments sometimes a dozen or more times a day, and waiting for a PV....something like 3 minutes I think. So the Red Lion Kadet boots 20 times faster.

That tells me something that I really like.

Some other things I noticed:

Their online help is best reached via F1. The menu help is a link to a non indexed pdf which is pretty good, and will be as good as a/b manuals, once Mike and the others get to work on adding some bookmarks and page-jumps to it.

If you need Ethernet, get the full blown G3 with multiple ports and ethernet.

My first impressions are very good. C3 software has only hiccupped once and it recovered all but the last 3 minutes of my work automatically (prompt to recover). I was running so many apps at the time, it's be hard to fault Crimson. I have also noticed that it hogs the foreground. If I want to click over to another application, C3 will take focus back often, but will relinquish on the 2nd try.

I expect the G3 to be faster more capable and more reliable. The extra time you might have to spend to roll your own clock sync routines, and page control registers, would be more than offset with FTView hassles and the boot times of the PV+ in my opinion.

No RSLinx enterprise to deal with, no Factory Talk Directory Services, updating the live running G304K was very quick, and the cable I have allows me to use both serial ports and test it on DH485 to the PLC, reload the application and be running again in under a minute...This little thing is color, has a nice sleek bezel and housing, and a pretty tough looking touchscreen. I don't see a compactflash on mine, but I have seen references to that feature...

I am rambling but back to creating an app.

Using their RSLogix import feature (download build 207) made it so easy. I chopped the .csv output from Logix in excel so it only had the tags I wanted, then it imported them and named them all based on the PLC address except for one which happened to have a symbol name.

Then those tags appeared on the right hand side, and I dragged and dropped them on the screens where I wanted...within an hour I had all the values on all the screens and only had to check a tickbox on the ones that were data entry fields.

The software has copy and paste properties features that make it easy to change the properties of lots of objects easily.

My favorite is the alignment markers that appear while moving things on screen. It makes neatness and alignment effortless.

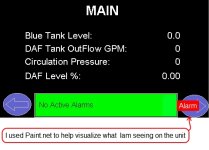

I haven't got into the "pretties" yet. I used a couple of the library buttons "as-is" and some arrow symbols. The screen is bright and colors are clear. It matches what you see at design time. The only snag I had graphically was the uncontained Alarm Ticker.

I did make a trend screen and datalog, and it was effortless and it actually worked on the first try! I am not sure how much data I can log or whether I need to manage the file size, but it has about 25 hours worth of data in it that I can graphically navigate. I would expect that it's possible to extract that data remotely too?

The screen is very responsive too. When I built my cable to be installed on the macine, I had a buddy watch the screen while I touched the already crimped pins on the test rack SLC 5/04. I wanted to be sure I had 2 and 3 in the right spots before I snapped them in the DB9 shell. The instant I made connection, he said "there it is". The first time viewing each page, the tags would be "---" and would be populated with data within a second. There was a longer delay when losing comms before the data on screen would go back to that unknown state, but that is normal, and it recovered nicely from losing comms, and then having them restored, unlike the PV+600 which doesn't recover nicely and can require a reboot following a comms loss.

I need to remember to add a tag with a link to the system comms status to trigger an alarm...

I don't think we will waste any time at least converting our old RIO and DH485 PV standards to shiny new G3s. The PV+ app on our forming machines is the property of the OEM, but the boss is supposed to be getting us a confidentiality agreement signed and I would do the development myself if necessary before we get rid of the PV600 Pluses, but if I was asked tomorrow, I would go with the full blown G3 to replace the PV+, or at least a model with Ethernet and a memory card slot.

Paul