matt.smith

Member

Hopefully an easy one.

In my program I am reading my analogue input values, low engineering values and high engineering values.

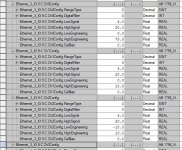

My analogue input values read ok when i look at F8[64] to F8[79] but my low engineering values (F8[200] to F8[215]) and high engineering values (F8[232] to F8[247]) are incorrect apart from the first one for each.

Looking at the 2nd attachment, because the engineering low or high channel values aren't together (in order) this is causing problems. Do I somehow need to make it read the first value then skip 5 values read then skip 5 and so on.

I could do a separate CPS for each but this doesn't seem very efficient.

Any help would be much much appreciated. Thank you

In my program I am reading my analogue input values, low engineering values and high engineering values.

My analogue input values read ok when i look at F8[64] to F8[79] but my low engineering values (F8[200] to F8[215]) and high engineering values (F8[232] to F8[247]) are incorrect apart from the first one for each.

Looking at the 2nd attachment, because the engineering low or high channel values aren't together (in order) this is causing problems. Do I somehow need to make it read the first value then skip 5 values read then skip 5 and so on.

I could do a separate CPS for each but this doesn't seem very efficient.

Any help would be much much appreciated. Thank you

.gif)