irondesk40

Member

i had previously posted asking if anyone has ever used a analog type sensor as a trim type dancer for the line speed of a AC drive.

I got some good advice, but thought it might be best if i posted with a seperate post about using the analog sensor to trim multiple AC drives.

Machine we are working on will now utilize a analog sensor as a dancer type configuration to trim the line speed of multiple AC drives. I had originally been told only one of the drives would need to be trimmed (have not actually seen the machine), but now being told by our Director that he wants this analog sensor to trim multiple motors.

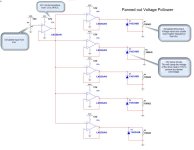

Confused on exactly how to feen a analog sensor into the plc and have it trim a scaled output to the drives for the required line speed. I understand how to scale the trim analog value in to represent a value of 0-100% that could then be used to multiply by the original value out to a motor, but confused on how to read that value in and if analog trim sensor in the middle which is 12ma and how to use any value below 12ma to lower the line speed and anything above 12ma to increase the line speed a percentage of lets say +- 20%.

Any suggestions would be greatly appreciated. At the moment pretty confused on which direction to go with this.

I got some good advice, but thought it might be best if i posted with a seperate post about using the analog sensor to trim multiple AC drives.

Machine we are working on will now utilize a analog sensor as a dancer type configuration to trim the line speed of multiple AC drives. I had originally been told only one of the drives would need to be trimmed (have not actually seen the machine), but now being told by our Director that he wants this analog sensor to trim multiple motors.

Confused on exactly how to feen a analog sensor into the plc and have it trim a scaled output to the drives for the required line speed. I understand how to scale the trim analog value in to represent a value of 0-100% that could then be used to multiply by the original value out to a motor, but confused on how to read that value in and if analog trim sensor in the middle which is 12ma and how to use any value below 12ma to lower the line speed and anything above 12ma to increase the line speed a percentage of lets say +- 20%.

Any suggestions would be greatly appreciated. At the moment pretty confused on which direction to go with this.