jcolley

Member

Greetings all. First post here, new to RL, MODBUS, pretty much all things PLC, so please forgive me if I'm asking dumb questions.

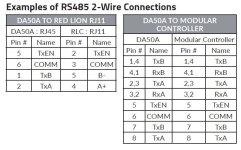

- I need to use a DA50A Group 2 to convert MODBUS RTU RS 485 data over to an AB PLC with L5K.

- I have the DA50A configured to serial port 2, verified RS 485 settings, universal modbus master, end device at address 1, and correct addresses being polled.

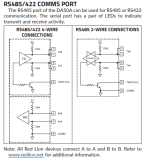

- I see a periodic green LED flash on the DA50 port 2, but never a red LED indicating a receipt.

- I have the blocks created directly under the port 2 with timed rate of 500 msec.

- When scoping the RS 485 lines with a Picoscope set to serial decode MODBUS RTU, I see no transmission from master.

- When measuring A and B to ground with DVM, I do not see the expected 2.2ish VDC that I measure on any other modbus networks. Picocope A/B channels correlate this.

- I have tried throwing a 120ohm resistor on just to see, no change.

I am certain the the slave device is working, there is an existing master working that the DA50 will replace.

I have an email in to Red Lion for assistance, but feeling pretty dumb I can't get this working, figured I'd ask here for some ideas.

Thanks in advance for any advice.

- I need to use a DA50A Group 2 to convert MODBUS RTU RS 485 data over to an AB PLC with L5K.

- I have the DA50A configured to serial port 2, verified RS 485 settings, universal modbus master, end device at address 1, and correct addresses being polled.

- I see a periodic green LED flash on the DA50 port 2, but never a red LED indicating a receipt.

- I have the blocks created directly under the port 2 with timed rate of 500 msec.

- When scoping the RS 485 lines with a Picoscope set to serial decode MODBUS RTU, I see no transmission from master.

- When measuring A and B to ground with DVM, I do not see the expected 2.2ish VDC that I measure on any other modbus networks. Picocope A/B channels correlate this.

- I have tried throwing a 120ohm resistor on just to see, no change.

I am certain the the slave device is working, there is an existing master working that the DA50 will replace.

I have an email in to Red Lion for assistance, but feeling pretty dumb I can't get this working, figured I'd ask here for some ideas.

Thanks in advance for any advice.