drbitboy

Lifetime Supporting Member

Another relative velocity problem, but non-linear this time.

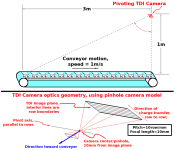

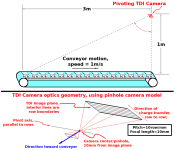

A quality control camera pivots (rotates) about a fixed axis to scan and inspect prints of a cat moving on, and with, a conveyor belt.

The camera is a TDI device (Note 1) with its rows parallel to the axis on which the camera rotates; the detector is the image plane.

To minimize TDI image smear, the rotation rate of the camera is varied such that, for the spot on the conveyor that is pointed to by the boresight at any given moment, the projection of that spot on the detector moves at the same speed and direction as the detector (row) charge transfer rate moves charge from row to row (refer to the TDI links in Note 1 below).

The camera is 1metre (1m) directly above the end of the conveyor; the start of the conveyor is 3m upstream of the end of the conveyor.

The focal length of the camera is 10mm; the pitch of pixel rows on the detector is 10rows/mm.

The image below is a rough visualization of the process using a pinhole camera model (Note 2); refer to Note 1 for details about TDI measurements.

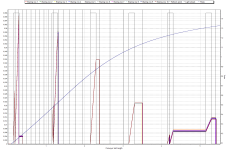

One cycle comprises two scans:

1) at the start of the cycle the camera has its boresight pointing straight down at the end of the conveyor, and it starts and continues the first scan towards the conveyor start at a rotation rate that varies to minimize smear on the detector with a charge transfer rate of 7row/s;

2) when the boresight reaches the start of the conveyor (3m from the end), it instantaneously changes the detector charge transfer rate to 150row/s (Note 3) and reverses the rotation direction to scan back toward the end of the conveyor, again varying the rotation rate to minimize smear;

3) the second scan and the cycle end when the boresight reaches the end of the conveyor i.e. the boresight points straight down again.

To plus or minus one millisecond, how long does each cycle take?

Notes

1) TDI = Time Delay and Integration cf. https://en.wikipedia.org/wiki/Time_delay_and_integration and https://dokumen.tips/documents/drif...on-scanning-time-delay-readout-ccd-drift.html).

2) Pinhole camera model: cf. https://en.wikipedia.org/wiki/Pinhole_camera_model

3) The detector charge transfer is in the same direction for both scans.

4) Ignore second order effects e.g. the differing geometry of the rows offset from the boresight, the thickness of the cat prints, assume the pivot axis is equivalent to the pinhole of the pinhole camer model etc.

5) Now I need to go calculate the answer; it's possible there is a singularity that prevents a solution with the numbers provided.

6) I am curious what PeterN's MathCad will do with this, because there is an analytical solution.

7) I know this is not a realistic process.

A quality control camera pivots (rotates) about a fixed axis to scan and inspect prints of a cat moving on, and with, a conveyor belt.

The camera is a TDI device (Note 1) with its rows parallel to the axis on which the camera rotates; the detector is the image plane.

To minimize TDI image smear, the rotation rate of the camera is varied such that, for the spot on the conveyor that is pointed to by the boresight at any given moment, the projection of that spot on the detector moves at the same speed and direction as the detector (row) charge transfer rate moves charge from row to row (refer to the TDI links in Note 1 below).

The camera is 1metre (1m) directly above the end of the conveyor; the start of the conveyor is 3m upstream of the end of the conveyor.

The focal length of the camera is 10mm; the pitch of pixel rows on the detector is 10rows/mm.

The image below is a rough visualization of the process using a pinhole camera model (Note 2); refer to Note 1 for details about TDI measurements.

One cycle comprises two scans:

1) at the start of the cycle the camera has its boresight pointing straight down at the end of the conveyor, and it starts and continues the first scan towards the conveyor start at a rotation rate that varies to minimize smear on the detector with a charge transfer rate of 7row/s;

2) when the boresight reaches the start of the conveyor (3m from the end), it instantaneously changes the detector charge transfer rate to 150row/s (Note 3) and reverses the rotation direction to scan back toward the end of the conveyor, again varying the rotation rate to minimize smear;

3) the second scan and the cycle end when the boresight reaches the end of the conveyor i.e. the boresight points straight down again.

To plus or minus one millisecond, how long does each cycle take?

Notes

1) TDI = Time Delay and Integration cf. https://en.wikipedia.org/wiki/Time_delay_and_integration and https://dokumen.tips/documents/drif...on-scanning-time-delay-readout-ccd-drift.html).

2) Pinhole camera model: cf. https://en.wikipedia.org/wiki/Pinhole_camera_model

3) The detector charge transfer is in the same direction for both scans.

4) Ignore second order effects e.g. the differing geometry of the rows offset from the boresight, the thickness of the cat prints, assume the pivot axis is equivalent to the pinhole of the pinhole camer model etc.

5) Now I need to go calculate the answer; it's possible there is a singularity that prevents a solution with the numbers provided.

6) I am curious what PeterN's MathCad will do with this, because there is an analytical solution.

7) I know this is not a realistic process.