I had to implement this once. We had a process where the consequences of not automatically restarting after a power failure were significantly more severe than the automatic restart. There were zero exposed moving parts, and significant chemical hazards involved if the fans weren't running.

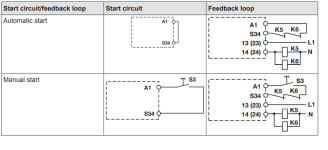

What we did was to leave the safety relay in monitored manual reset, but to wire an output relay from the PLC to permit the PLC to reset the safety circuit, in parallel with the physical reset pushbutton.

Inside the PLC logic, we had a latched bit which monitored the state of the safety relay. At power up, we checked the bit and the logic essentially said "if, and only if, the safety relay was healthy when the PLC went down, try exactly once to reset it 5 seconds after power on".

This means that if the safeties were tripped when the power went off, the safeties stayed tripped when it came back on. If someone presses an e/stop while the power is off, safeties remain tripped when the power comes back on*. But if the safeties were healthy when the power went out, and no e/stop was pressed when the power came back on, the safety circuit would get reset and the system would auto restart.

(*provided the e/stop wasn't both pressed and reset again while the power remained off).

Of course, you absolutely must do an extensive risk assessment and document, document, document. If you had any guarded areas, I personally would never sign off on this. If you had any exposed moving parts, same deal, even if they were protected by light curtains. My application was closer to a laboratory environment than an industrial environment, so the level of physical/mechanical hazards present permitted the idea to be entertained.