Hello, A couple of questions regarding NEMA schematics and terminal block labeling.

1) I am familiar with the DIN designations for components on an electrical schematic, =System+Location-Component:Terminal. What is the equivalent of this in use on NEMA schematics? I have seen "Component-Terminal" but this doesn't give any location or system info. I'm also not sure what to do when it comes to terminal blocks, hence the next question.

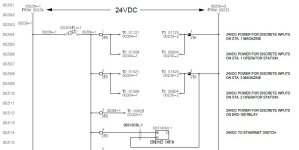

2) Say for example I have a set of 20x 2-level terminal blocks, one layer for 24V and the other for 0V, jumpered all the way across. The terminal blocks are labeled TB1000. How would you go about labeling the blocks themselves? Would you put number labels on each block or just +/- labels? Or both? Should they be labeled/ordered 1-20 or something else, considering that there are 2 layers?

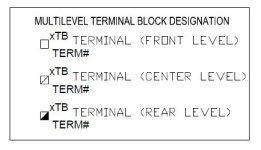

3) If one wire is feeding all positive terminals of those 20 blocks, and the rest of the wires are outgoing from the blocks on both the top and the bottom (for convenience depending on location of the component they are feeding, giving essentially 39 supply terminals), how would I differentiate between the top/bottom + terminals on terminal block 18, for example, on a schematic? I have seen an example like TB1000-18.1/TB1000-18.2, where 18.1 was the top and 18.2 was the bottom, but I'm wondering if there is a standardized way of doing this. And this example doesn't work for multi-layer blocks, because nothing here is designating which layer I'm talking about. Is there a preferred way of doing this?

Thanks!

1) I am familiar with the DIN designations for components on an electrical schematic, =System+Location-Component:Terminal. What is the equivalent of this in use on NEMA schematics? I have seen "Component-Terminal" but this doesn't give any location or system info. I'm also not sure what to do when it comes to terminal blocks, hence the next question.

2) Say for example I have a set of 20x 2-level terminal blocks, one layer for 24V and the other for 0V, jumpered all the way across. The terminal blocks are labeled TB1000. How would you go about labeling the blocks themselves? Would you put number labels on each block or just +/- labels? Or both? Should they be labeled/ordered 1-20 or something else, considering that there are 2 layers?

3) If one wire is feeding all positive terminals of those 20 blocks, and the rest of the wires are outgoing from the blocks on both the top and the bottom (for convenience depending on location of the component they are feeding, giving essentially 39 supply terminals), how would I differentiate between the top/bottom + terminals on terminal block 18, for example, on a schematic? I have seen an example like TB1000-18.1/TB1000-18.2, where 18.1 was the top and 18.2 was the bottom, but I'm wondering if there is a standardized way of doing this. And this example doesn't work for multi-layer blocks, because nothing here is designating which layer I'm talking about. Is there a preferred way of doing this?

Thanks!