Goody

Member

Here is a new angle I would like peoples advice or help with!

Any suggestions to help with my programming or to be more exact my HMI programming would be useful.

Not the actual programming of HMI's (I have been doing them for years) but the layout and sequence and especially the esthetics (aesthetics)

I dont mean my buttons or data inputs are too big or all over the place - they are usually rigidly lined up and functional.

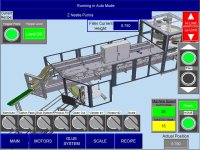

Sometimes though, I see someone elses HMI work and I have immediately thought 'ooh this is pleasing to the eye' but I don't know why.

I am a logic thinker - not an artist. (I think it is to do with a dominant left or right brain) I am also dyslexic (as are many men) and I have thought maybe that has something to do with it.

Also, if I am being honest, some of my HMI's seem to baffle the operators. Maybe not baffle but sometimes they struggle to navigate to the right page.

I watch them try navigate, and it seems blindingly obvious to me which button they should press but I watch them hovering over several choices and going the wrong way

So any hints or advice from some of you great hmi designers would be appreciated.

Any suggestions to help with my programming or to be more exact my HMI programming would be useful.

Not the actual programming of HMI's (I have been doing them for years) but the layout and sequence and especially the esthetics (aesthetics)

When I program an HMI from scratch, I give a lot of thought to the sequential flow of the pages and order of importance. But, to be truthful, I often struggle to make them look 'pretty' or appealing.(ěs-thět'ĭk)

adj.

- Relating to the philosophy or theories of aesthetics.

- Of or concerning the appreciation of beauty or good taste: the aesthetic faculties.

- Characterized by a heightened sensitivity to beauty.

- Artistic: The play was an aesthetic success.

- Informal Conforming to accepted notions of good taste.

I dont mean my buttons or data inputs are too big or all over the place - they are usually rigidly lined up and functional.

Sometimes though, I see someone elses HMI work and I have immediately thought 'ooh this is pleasing to the eye' but I don't know why.

I am a logic thinker - not an artist. (I think it is to do with a dominant left or right brain) I am also dyslexic (as are many men) and I have thought maybe that has something to do with it.

Also, if I am being honest, some of my HMI's seem to baffle the operators. Maybe not baffle but sometimes they struggle to navigate to the right page.

I watch them try navigate, and it seems blindingly obvious to me which button they should press but I watch them hovering over several choices and going the wrong way

So any hints or advice from some of you great hmi designers would be appreciated.