MaxK

Member

Wow! what we got here:

1. 30 posts

2. another pdf by Peter Nachtwey

3. Another mention from Peter Nachtwey about “real control experts”, about “solving” by approximation, using the Euler method without checking the original problem.

result:

1. the plant is 1/s^2 i.e. 2nd order integrator, i.e. unstable object of the 2nd order

2. An unstable 2nd order object is extremely sensitive to any dead band (mechanical, mathematical, algorithmic, etc.)

is it was'nt clear from 1-st post?

Oh yah! Don’t forget to spent next 30 posts to find THRORETICAL models poles

s^2+k*kd*s+kp*k = 0

Drbitboy, why do you use TF for SP, but not for disturbance?

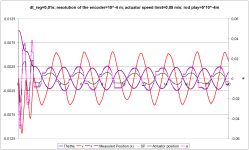

it is obvious from the convulsions of the system in the video that there are huge "dead bands"

post 18. PIC 459 PIC 616 both not good - no process reaction to CV pitches = "dead bands"

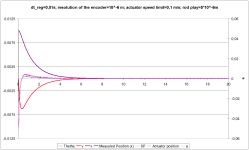

Geniusintraining Continue to provide information so that it is as difficult as possible to understand it (curves to fit on 3 pixels, so that it was not clear the PID controller update time and the integration frequency of I-term etc)

the person building the PID trainer has no idea about control systems theory

Ouch! yeah! Peter, when you replace a metal ball with a ping pong ball, it's not about mass, it's about drag forces (air, friction, etc.), in real conditions drag forces for a ping pong ball are comparable to "gravity" are capable of both reducing speed and acceleration. And for this task, a differential equation in partial derivatives is required.

1. 30 posts

2. another pdf by Peter Nachtwey

3. Another mention from Peter Nachtwey about “real control experts”, about “solving” by approximation, using the Euler method without checking the original problem.

result:

1. the plant is 1/s^2 i.e. 2nd order integrator, i.e. unstable object of the 2nd order

2. An unstable 2nd order object is extremely sensitive to any dead band (mechanical, mathematical, algorithmic, etc.)

is it was'nt clear from 1-st post?

Oh yah! Don’t forget to spent next 30 posts to find THRORETICAL models poles

s^2+k*kd*s+kp*k = 0

Drbitboy, why do you use TF for SP, but not for disturbance?

it is obvious from the convulsions of the system in the video that there are huge "dead bands"

post 18. PIC 459 PIC 616 both not good - no process reaction to CV pitches = "dead bands"

Geniusintraining Continue to provide information so that it is as difficult as possible to understand it (curves to fit on 3 pixels, so that it was not clear the PID controller update time and the integration frequency of I-term etc)

Glad to meet a person with a great sense of humor, check out the joke:Sorry but I have no idea what that is... I know just enough to be dangerous

the person building the PID trainer has no idea about control systems theory

Ouch! yeah! Peter, when you replace a metal ball with a ping pong ball, it's not about mass, it's about drag forces (air, friction, etc.), in real conditions drag forces for a ping pong ball are comparable to "gravity" are capable of both reducing speed and acceleration. And for this task, a differential equation in partial derivatives is required.